ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes Mainly used in Heat Exchanger and Boiler.

ASTM A179/ASME SA179 U Bend Heat Exchanger Tubes Quick Details

Manufacture:Seamless process ,cold drawn.

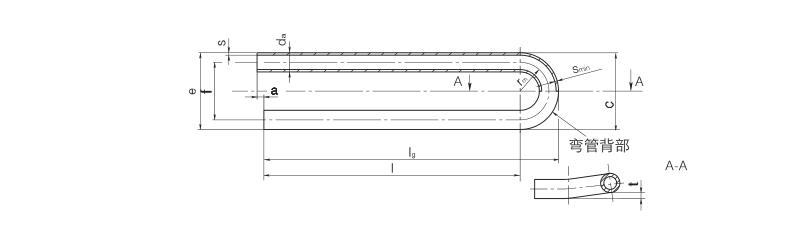

Bending Details: According to Bending Drawings.

Wall thickness(WT): 1.65 mm——2.77 mm.

Outer diameter (OD): 19.05mm - 38.1mm

Length: 6M or specified length as required, the longest is 26 meters.

Ends: Plain End

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T/T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Wooden Boxes,Crates (steel/wooden) or as required

Chemical Composition of ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

| Material | Chemical Composition(%) | ||||

| C | Si | Mn | P | S | |

| STM A179/ASME SA179 | 0.06-0.18 | ≤ 0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

Mechanical Propertie of ASTM A179/ASME SA179 U Bend (U Bent) Heat Exchanger Tubes

| Grade | ASTM A179 |

| Tensile Strength(MPa) | ≥325 |

| Yield Strength(MPa) | ≥180 |

| Elongation,% | ≥35 |

| Hardness, HRB | ≤72 |

Specifications of ASTM A179/ASME SA179 U Bend Heat Exchanger Tubes

Bending Details: Can Accord to Bending Drawings.

Technical Parameters

Outer diameter: 12.7-38 mm

The bending radius is from 1.5 times the outer diameter to 1250 mm. The outer diameter is over 28mm,

The minimum bend radius can be further discussed.

Straight pipe length is the shortest 1000mm

Straight pipe length up to 12000mm

The bending radius is below 1000mm and heat treatment is required.

Bent pipe technology standard

Technical Standard 7-2-1179

DIN 2879, TEMA RCB 2.31

Can be specified according to customer requirements. Can also follow some general techniques

Specifications.

Heat treatment

If requested by the customer, we add a straight pipe section with a minimum of 150mm according to the elbow.

Heat treatment is performed.

The computer controls the heat treatment furnace and records all the data.

The tube is filled with a protective gas - argon.

Annealing Status:

|

Annealing

|

||

| Solution annealing | Stress relief annealing | Stabilized annealing |

Hydrostatictest

All U-tubes are subjected to a hydrostatic test after heat treatment.

The test time is not less than 5 seconds at the set pressure.

All tubes were blown dry and carefully cleaned after the test.

Measuring, cutting, deburring, cleaning

Accurately measure U-tubes according to relevant standards or customer requirements.

All pipes should be cut to length, deburred, and air dried to the inner wall.

Seal the ends with a plastic cap before packing.

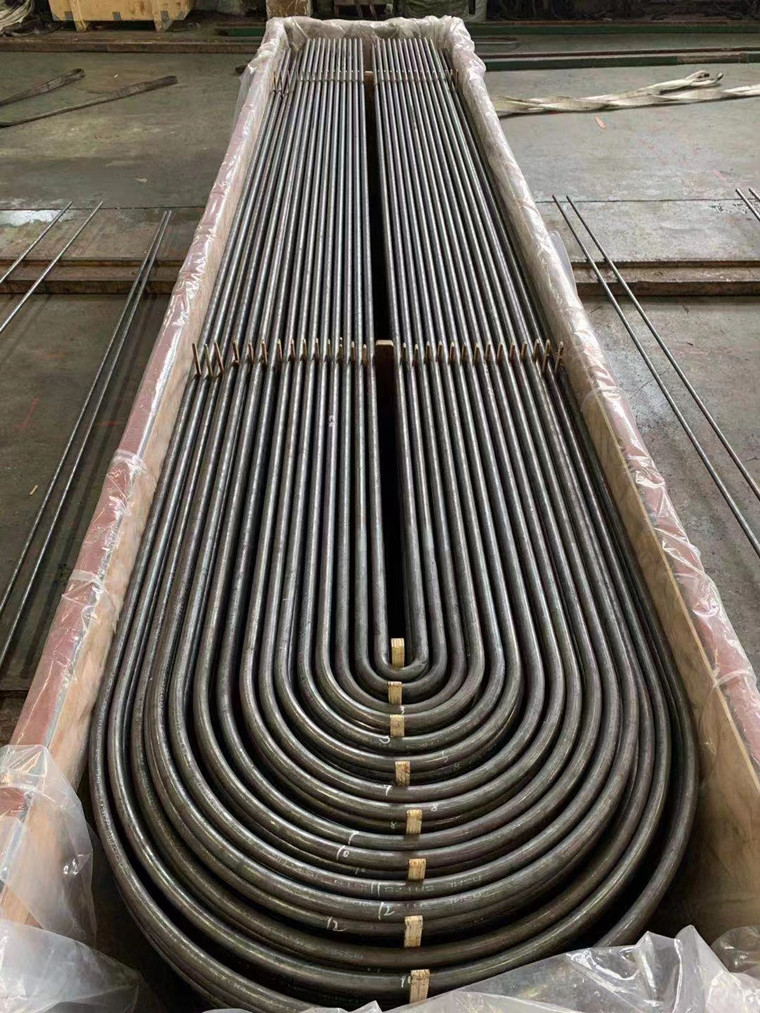

Package

Use a strong, and depending on the distance to the destination, choose an open or sealed wooden case with a maximum weight of 8,000kg.

Both ends of the pipe are sealed with a plastic cap

Each elbow radius specification is vertically separated

Each row is separated by a chlorine-free plastic sheet every two meters

Each bundle of tubes is wrapped in plastic sheet

Customers can provide packaging drawings or Sandvik ready to package

The packing list should be packed in a plastic bag and placed in a wooden box for detailed review at the time of arrival - including all bend radii and pipe lengths.

Packaging picture of ASTM A179/ASME SA179 U Bend Heat Exchanger Tubes

![field:title/]](/uploads/220224/1-2202241S034328.png)

![field:title/]](/uploads/211227/1-21122G9544a15.jpg)