ASTM A213 ASME SA213 TP310S Seamless Steel Tubes

ASTM A213 ASME SA-213 TP310S Seamless Steel Tubes

TP310S (0Cr25Ni20/0Cr25Ni20Si2), heat-resistant stainless steel, commonly known as 310S, also known as 2520 duplex stainless steel, used in the manufacture of high-temperature furnace tubes.TP310S steel is austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance. Because of the higher percentage of chromium and nickel, TP310S stainless steel has much better creep strength and can continue to operate at high temperatures. It has good High temperature resistance, the highest working temperature is 1200 ℃, and the continuous use temperature is 1150 ℃.

ASTM A213 ASME SA-213 TP310S Seamless Steel Tubes

Standard: ASTM A213, ASME SA213

Equivalent Standards: EN 10216-5, DIN 17458, GOST 9941-81, GOST 9940-81

ASTM A213/ASME SA213

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Company Name: beite steel pipe

Country/Region: China

Product Name:ASTM A213 TP310S Stainless Steel Tube

FOB Price: US $2,000-4,200 / Ton | 0.5 Ton/Tons (Min. Order)

Payment:L/C or T/T

Package:Standard export package,suit for all kinds of transport, or as required

Certificate:ISO 9001-2000,PED 97/23/EC,ASME,DNV

Tube Range: 1/2" OD - 12" OD, Guage: 25 SWG - 10 SWG

Tube Type: Round, Square, Rectangle, Coil, "U" Shape, Hydraulic & Honed Tubes

Materials and Manufacture

Manufacture and Condition

Tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified.

Heat Treatment:

ASTM A213 TP310 stainless steel is an austenitic chromium-nickel stainless steel.

Austenitic Stainless Steels—All austenitic tubes shall be furnished in the heat-treated condition, and shall be heat treated in accordance with the requirements of Table 1.Alternatively, immediately after hot forming, while the tem-perature of the ASTM A213 ASME SA-213 TP310S seamless steel tube is not less than the minimum solution or stabilization treatment temperature specified in Table 1, tubes may be individually quenched in water or rapidly cooled by other means (direct quenched).

The main reason for annealing the TP310 stainless steel tube is to produce a recrystallized fine structure to achieve a uniform grain size and decompose harmful chromium carbide deposits.

Requirements for heat treatment and grain size of ASTM A213 ASME SA-213 TP310S seamless steel tube

| Grade | Heat treatment | Solution treatment temperature,℃ | Cooling medium | ASTM grain size class number |

| SA-213 TP310S | solution treatment. | 1900 [1040] F | Water cooling or rapid cooling | --- |

Table 1

ASTM A213 TP310S Stainless Steel Tube Chemical Composition(%)

| Grade | Chemical Composition(%) | |||||||

| C | Mn | P | S | Si | Cr | Ni | Fe | |

| ASTM A213 TP310S | ≤0.08 | ≤2 | ≤0.045 | ≤0.03 | ≤1.50 | 24-26 | 19-22 | Balance |

ASTM A213 TP310S Stainless Steel Tube Mechanical & Physical Properties

| Grade | Mechanical & Physical Properties | ||||

| Density | Melting Point | Tensile Strength | Yield Strength | Elongation | |

| ASTM A213 TP310S | 8.0 g/cm3 | 1454°C(2650 °F) | Psi-75000,Mpa-515 | Psi-30000,Mpa-205 | 35% |

Outside Diameter & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

Wall thickness & Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Application of ASTM A213 TP310S Stainless Steel Seamless Tubes

ASTM A213 TP310S stainless steel seamless tube can be used to manufacture furnace tubes, boiler superheaters, and heat exchanger pipe fittings.Usually shows good high temperature strength, creep resistance and corrosion resistance. Therefore, they are widely used in furnace parts in the heat treatment industry. TP310S stainless steel seamless tube is also used in the chemical processing industry to carry hot concentrated acid, ammonia and disulfide in the food processing industry.

Product Features of ASTM A213 TP310S Stainless Steel Seamless Tubes

1) ASTM A213 TP310S stainless steel is austenitic chromium-nickel stainless steel, which has good oxidation resistance, corrosion resistance and high temperature resistance. Because of the higher percentage of chromium and nickel, it has much better creep strength and can be sustained at high temperatures. Operation, has good high temperature resistance. Due to the high content of nickel (Ni) and chromium (Cr), it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. High temperature resistant steel pipes are specially used in the manufacture of electric furnace tubes.

2) After increasing the carbon content in austenitic stainless steel, the strength is improved due to its solid solution strengthening effect.

3) The chemical composition characteristics of austenitic stainless steel are based on chromium and nickel with the addition of elements such as molybdenum, tungsten, niobium and titanium. Because its structure is a face-centered cubic structure, it has high strength and creep strength at high temperatures . The melting point is 1470℃, and it starts to soften at 800℃, and the allowable stress continues to decrease.

4) When HNO3≦70%, the corrosion resistance of stainless steel is mainly determined by the amount of chromium in the steel. In higher concentrations of nitric acid, although the amount of chromium in steel also plays a role, the content of impurities (Si, P, S, etc.) in the steel also has an important effect. TP310S steel has low carbon content and high chromium content, and its impurity content is strictly controlled. Therefore, in nitric acid with a concentration of ≦80%, its corrosion resistance is far better than 18-8 (00Cr18Ni10) and high-silicon stainless steel (00Cr18Ni15Si4). Only when the acid concentration is ≧85%, high silicon stainless steel can show its superiority.

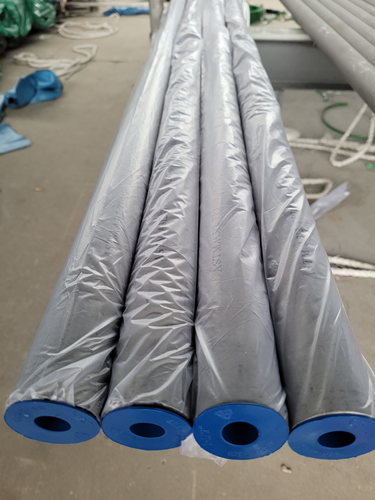

Photos of ASTM A213 TP310S Seamless Steel Tubes

Please fill the following form.

![field:title/]](/uploads/230313/1-230313123913C5.jpg)

![field:title/]](/uploads/221029/1-221029152602104.png)

![field:title/]](/uploads/221029/1-221029151P2200.png)

![field:title/]](/uploads/200115/1-200115110515418.png)

![field:title/]](/uploads/191012/1-19101213593J94.jpg)

![field:title/]](/uploads/220915/1-220915122A2E0.jpg)

![field:title/]](/uploads/200203/1-2002031G403Z3.jpg)