ASTM B861 Grade 9 Titanium Alloy Seamless Pipe

ASTM B861 Grade 9 Titanium Alloy Seamless Pipe

ASTM B861 Grade 9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium) Seamless Pipe

Standard:

ASTM B861 Standard Specification for Titanium and Titanium Alloy Seamless Pipe

ASTM B861 Grade 9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium) Seamless Pipe intended for general corrosion resisting and elevated temperature service

ASTM B861 Grade 9 Titanium Alloy Seamless Pipe Quick Details

Manufacture:Seamless process ,Cold-drawn

Wall thickness(WT): 0.5 mm-12.7 mm.

Outer diameter (OD): 12.7 mm-219 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms: T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Manufacture

Seamless pipe may be manufactured by any method that will yield a product meeting the requirements of this specification.

Unless specified, cold worked pipe shall be heat treated at a temperature of not less than 1000°F (538°C). Hot worked pipe finishing above 1400°F (760°C) need not be further heat treated. The minimum heat treat conditions for ASTM B861 Grade 9 Titanium Alloy Seamless Pipe delivered in the stress relieved condition shall be 600°F (316°C) for at least 30 min.

ASTM B861 Grade 9 Titanium Alloy Seamless Pipe—coldworked and stress-relieved or annealed,

ASTM B861 Grade 9 Titanium Alloy Seamless Pipe—transformed-beta condition.

Chemical Composition of ASTM B861 Grade 9 Titanium Alloy Seamless Pipe

| Chemical Composition(%) | |||||||||

| C,max | O,max | N,max | H,max | Fe,max | Al,max | V,max |

Other Elements, max. each |

Other Elements, max. total |

Ti |

| 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | 0.1 | 0.4 | Balance |

Product Analysis

When requested by the purchaser and stated in the purchase order,an analysis of chemical composition will be made on the finished product.

The product analysis tolerances, listed in Table 2 do not broaden the specified analysis requirements, but cover variations between different laboratories in the measurement of chemical content.

| Element | Product Analysis Limits, Permissible Variation | |

| max or Range,% | in Product Analysis | |

| Aluminum | 0.5 to 2.5 | ±0.20 |

| Aluminum | 2.5 to 6.75 | ±0.40 |

| Carbon | 0.10 | +0.02 |

| Chromium | 0.1 to 0.2 | ±0.02 |

| Chromium | 5.5 to 6.5 | ±0.30 |

| Hydrogen | 0.02 | +0.002 |

| Iron | 0.80 | +0.15 |

| Iron | 1.2 to 1.8 | ±0.20 |

| Molybdenum | 0.2 to 0.4 | ±0.03 |

| Molybdenum | 1.5 to 4.5 | ±0.20 |

| Molybdenum | 14.0 to 16.0 | ±0.50 |

| Nickel | 0.3 to 0.9 | ±0.05 |

| Niobium | 2.2 to 3.2 | ±0.15 |

| Niobium | >30 | ±0.50 |

| Nitrogen | 0.05 | +0.02 |

| Oxygen | 0.30 | +0.03 |

| Oxygen | 0.31 to 0.40 | ±0.04 |

| Palladium | 0.01 to 0.02 | ±0.002 |

| Palladium | 0.04 to 0.08 | ±0.005 |

| Palladium | 0.12 to 0.25 | ±0.02 |

| Ruthenium | 0.02 to 0.04 | ±0.005 |

| Ruthenium | 0.04 to 0.06 | ±0.005 |

| Ruthenium | 0.08 to 0.14 | ±0.01 |

| Silicon | 0.06 to 0.40 | ±0.02 |

| Vanadium | 2.0 to 4.5 | ±0.15 |

| Vanadium | 7.5 to 8.5 | ±0.40 |

| Zirconium | 3.5 to 4.5 | ±0.20 |

| Residuals A (each) | 0.15 | +0.02 |

Tensile Requirements of ASTM B861 Grade 9 Titanium Alloy Seamless Pipe

| Grade | Tensile Strength, min | Yield Strength (0.2 % Offset) | Elongation 2 in. Or 50 mm | ||||

| ksi | (MPa) | min. | max. | gage length,min % | |||

| ksi | (MPa) | ksi | (MPa) | ||||

| 9 | 90 | (620) | 70 | (483) | ... | ... | 15 |

| 9 E | 90 | (620) | 70 | (483) | ... | ... | 12 |

| 9 F | 125 | (860) | 105 | (725) | ... | ... | 10 |

E Properties for material in transformed-beta condition.

F Properties for cold-worked and stress-relieved material.

Permissible Variations in Dimensions

Diameter—Variations in outside diameter shall not exceed those prescribed in Table 4.

Thickness—The variation in thickness at any point shall not be more than ±12.5 % of the nominal wall thickness specified.

Length—Pipe shall be furnished in lengths as specified in the purchase order. No pipe shall be under the specified length and not more than 1 ⁄ 4 in. (6.4 mm) over that specified.

Straightness—The pipe shall be free of kinks and bends and the maximum bow of lengths up to 10 ft (3 m) shall not exceed 1:500. For lengths greater than 10 ft, the maximum bow shall not exceed 1:400.

| Nominal Outside Diameter (NPS) | Permissible Variations in Outside Diameter | |

| Over | Under | |

| 1 ⁄ 8 in. to 1 1 ⁄ 2 in. (3.2 mm to 38 mm) | 1 ⁄ 64 in. (0.397 mm) | 1 ⁄ 32 in. (0.794 mm) |

| over 1 1 ⁄ 2 in. to 4 in. (38 mm to 102 mm) | 1 ⁄ 32 in. (0.794 mm) | 1 ⁄ 32 in. (0.794 mm) |

| over 4 in. to 8 in. (102 mm to 203 mm) | 1 ⁄ 1 6 in. (1.588 mm) | 1 ⁄ 32 in. (0.794 mm) |

| over 8 in. to 18 in. (203 mm to 432mm) | 3 ⁄ 32 in. (2.382 mm) | 1 ⁄ 32 in. (0.794 mm) |

Finish

The finished pipe shall have smooth ends, be free of burrs, and shall be free of injurious external and internal imperfections of a nature that will interfere with the purpose.

Testings

Bending Test

Pipe 2 in. (51 mm) and under in nominal diameter,shall be capable of being bent cold through 90° around a cylindrical mandrel which is twelve times the nominal diameter of the pipe, without developing cracks.

Flattening Test

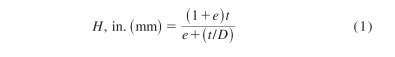

Seamless pipe shall be capable of withstanding, without cracking, flattening under a load applied gradually at room temperature until the distance between the load platens is H inches. H is calculated as follows:

H = Minimum flattened height, in. (mm),

t = nominal wall thickness, in. (mm) and,

D = nominal pipe diameter, in. (mm) (not pipe size),

e = 0.04 through 1 in. pipe size, and

e = 0.06 over 1 in. pipe size.

For ASTM B861 Grade 9 Titanium Alloy Seamless Pipe not shown above, the requirements for the flattening test shall be negotiated between the manufacturer and purchaser.

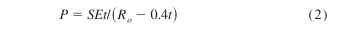

Hydrostatic Test

Each length of pipe shall withstand, without showing bulges, leaks, or other defects, an internal hydrostatic pressure that will produce in the pipe wall a stress of 50 % of the minimum specified yield strength at room temperature. This pressure shall be determined by the equation:

P = minimum hydrostatic test pressure, psi (or MPa),

S = allowable fiber stress of one-half the minimum yield strength, psi (or MPa),

t = wall thickness, in. (or mm),

R o = outside tube radius, in. (or mm), and

E = 1.0 seamless pipe.

The maximum hydrostatic test pressure shall not exceed 2500 psi (17.2 MPa) for sizes 3 in. (76 mm) and under, or 2800 psi (19.3 MPa) for sizes over 3 in. (76 mm). Hydrostatic pressure shall be maintained for not less than 5 s.

Terminology

lot, n—a number ofpieces ofpipe ofthe same nominal size and wall thickness manufactured by the same process from a single heat of titanium or titanium alloy and heat treated by the same furnace parameters in the same furnace.

seamless pipe, n—a hollow tubular product produced with a continuous periphery in all stages of manufacture.

Certification

We supply at least one copy of the report certifying that the material supplied has been manufactured, inspected, sampled, and tested in accordance with the requirements of this specification and that the results of chemical analysis, tensile, and other tests meet the requirements of this specification for the grade specified. The report shall include results of all chemical analysis, tensile tests, and all other tests required by the specification.

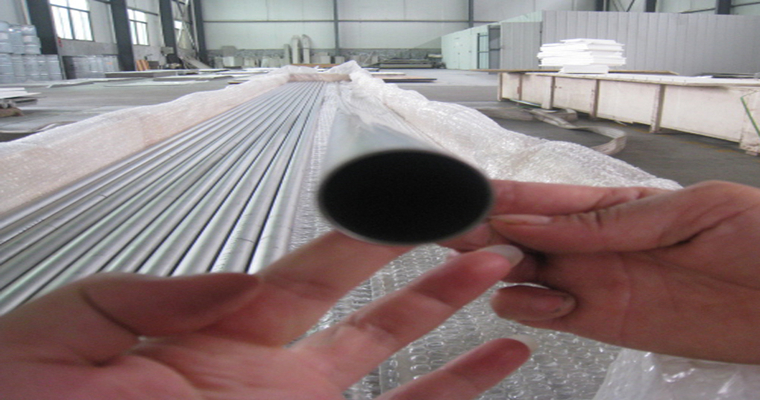

Photo of ASTM B861 Grade 9 Titanium Alloy Seamless Pipe

![field:title/]](/uploads/221201/1-2212011A425N2.jpg)

![field:title/]](/uploads/221201/1-2212011H352B7.jpg)

![field:title/]](/uploads/221201/1-221201163P3326.jpg)

![field:title/]](/uploads/221201/1-22120116141H01.jpg)

![field:title/]](/uploads/221201/1-22120115340J15.jpg)

![field:title/]](/uploads/221201/1-221201151533630.jpg)

![field:title/]](/uploads/221201/1-22120110332b02.png)