EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes for pressure purposes (power plant boiler tubes/oil refinery boiler tubes)

EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes is a high temperature alloy steel, a type of ferritic/martensitic stainless steel. It contains high levels of alloying elements such as chromium, molybdenum, vanadium and niobium, which work together to significantly enhance the corrosion resistance, heat resistance and high temperature strength of the steel tube.

1.4903 X10CrMoVNb9-1 Steel

1.4903 X10CrMoVNb9-1 Steel can maintain stable performance under extreme working conditions. This steel is widely used in high temperature and high pressure environments such as power stations, especially in nuclear power plants, where it is widely used in the manufacture of equipment such as reactor pressure vessels, heat exchangers, steam generators, and piping systems. Its excellent heat resistance and resistance to stress corrosion cracking make 1.4903 X10CrMoVNb9-1 steel perform particularly well in these extreme environments.

Standard:BS EN 10216-2:2013

Seamless steel tubes for pressure purposes — Technical delivery conditions Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties.

EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes Quick Details

Manufacture:Seamless process

Wall thickness(WT): 2.1mm——20 mm.

Outer diameter (OD): 21 mm——509mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 25-45 days after payment

Surface: Tubes will be varnished to prevent rust.

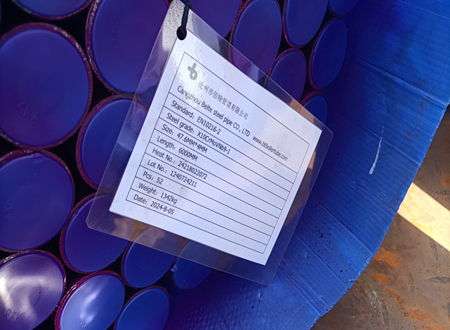

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Manufacturing process

steel making process

1.4903 X10CrMoVNb9-1 Steels shall be fully killed.

The tubes shall be manufactured by a seamless process.

We will hot work or cold work the tube according to the actual requirements. Tubes should be cold-finished prior to heat treatment.

Heat Treatment For EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

| Steel Grade |

Heat treatment a |

Austenizing | Tempering | |||

| Steel Name | Steel Number | Temperature °C |

Cooling Medium |

Temperature °C |

Cooling medium |

|

| X10CrMoVNb9-1 | 1.4903 |

+NT

c

|

1040 to 1090 | air | 730 to 780 | air |

|

a:+N = Normalizing, +NT = Normalizing + Tempering, +QT = Quenching + Tempering (air or liquid), +I = Isothermal Annealing. c :For these steel grades it may be necessary in the case of wall thickness T above 25 mm or T/D > 0,1 5 to apply quenching and tempering in order to achieve the intended structure and material properties . The decision shall be left to the discretion of the manufacturer but shall be stated to the customer at the time of enquiry and order. Steel tubes treated in such a way shall be designated by the steel name supplemented by the symbol “+QT “. |

||||||

Chemical Composition of EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

| Steel Grade | Steel Number | C | Si | Mn |

P

max

|

S

max

|

Cr |

| X10CrMoVNb9-1 | 1.4903 |

0.08-0.12

|

0.20-0.50

|

0.30-0.60

|

0.020 | 0.010 |

8.00-9.50

|

| Mo | Ni | Al tot | Cu | Nb | Ti | V |

Cr+Cu

+Mo+Ni

|

Others |

|

0.85-1.05

|

≤0.40

|

≤0.040 |

≤0.30 c

|

0.06-0.10

|

- |

0.18-0.25

|

- |

N=0.030-0.070

|

1.Elements not included in this Table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All

Mechanical Properties of EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

| Steel Grade | Upper yield strength or proof strength R eH or Rp 0,2 for Wall Thickness Tmin. |

Tensile Strength Rm |

Elongation A min. % a |

|||||

| Steel Name | Steel Number | T ≤ 16 | 16 < T ≤ 40 | 40 < T ≤ 60 | 60 < T ≤ 100 | l | t | |

| MPa * | MPa * | MPa * | MPa * | MPa * | ||||

| X10CrMoVNb9-1 | 1.4903 | 450 | 450 | 450 | 450 | 630 to 830 | 19 | 17 |

| Steel Grade | Impact properties | |||||

|

Minimum average absorbed energy KV 2 J at a temperature of °C |

||||||

| Steel Name | Steel Number | l | t | |||

| 20 | 0 | -10 | 20 | 0 | ||

| X10CrMoVNb9-1 | 1.4903 |

40 c f

|

- | - |

27 c

|

- |

Minimum proof strength R p0,2 at elevated temperature of EN 10216-2 1.4903 X10CrMoVNb9-1 Seamless Steel Tubes

| Steel Grade | Wall thickness mm | Minimum proof strength R p0,2 MPa at a temperature of °C | ||||||||||

| Steel name | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

| X10CrMoVNb91 | ≤100 | 410 | 395 | 380 | 370 | 360 | 350 | 340 | 320 | 300 | 270 | 215 |

Dimensions tolerances of EN 10216-2

Tolerances on outside diameter and wall thicknes

| Outside Diameter D mm |

Tolerances on D |

Tolerances on T for a T/D ratio | |||

| ≤ 0,025 |

> 0,025 ≤ 0,050 |

> 0,050 ≤ 0,10 |

> 0,10 | ||

| D ≤ 219,1 |

± 1% or ± 0.5mm whichever is the greater |

± 12,5% or ± 0.4mm whichever is the greater | |||

| D > 219,1 | ± 20% | ± 15% | ± 12,5% | ± 10% a | |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances on inside diameter and wall thickness

| Tolerances on inside diameter | Tolerances on T for a T/d ratio | |||||

| d | d min | ≤ 0,03 |

> 0,03 ≤ 0,06 |

> 0,06 ≤ 0,12 |

> 0,12 | |

| ± 1% or ± 2 mm whichever is the greater |

(+ 2% ,0)or (+ 4 mm,0) |

whichever is the greater | ± 20% | ± 15% | ± 12,5% | ± 10% a |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||||

Tolerances on outside diameter and minimum wall thickness

| Outside diameter D mm | Tolerances on D | Tolerances on T min for a T min /D ratio | |||

| ≤ 0,02 |

> 0,02 ≤ 0,04 |

> 0,04 ≤ 0,09 |

> 0,09 | ||

| D ≤ 219,1 |

± 1% or ± 0.5mm whichever is the greater |

(+ 28%,0) or (+ 0.8 mm,0) whichever is the greater | |||

| D > 219,1 |

+ 50% 0 |

+ 35% 0 |

+ 28% 0 |

+ 22% a 0 |

|

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances on inside diameter and minimum wall thickness

|

Tolerances on inside diameter |

Tolerances on T min for a T min /d ratio |

|||

| d | d min | ≤ 0,05 |

> 0,05 ≤ 0,1 |

> 0,1 |

|

± 1% or ± 2 mm whichever is the greater |

(+2%,0) or (+ 4 mm,0) whichever is the greater |

+ 35% 0 |

+ 28% 0 |

+ 22% a 0 |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||

Tolerances on exact lengths

Dimension in mm

| Length L | Tolerance on exact length |

| L ≤ 6000 |

+10 0 |

| 6000 < L ≤ 12 000 |

+15 0 |

| L > 12 000 |

+ by agreement 0 |

Straightness

The deviation from straightness of any tube length L shall not exceed 0,001 5 L. Deviations from straightness over any one metre length shall not exceed 3 mm.

Preparation of ends

The tubes shall be delivered with bevelled ends (see Figure 1). The bevel shall have an angle α of 30°(+5°,0°) with a root face C of 1,6 mm ± 0,8 mm, except that for wall thickness T greater than 20 mm, an agreed alternative bevel may be specified.

TESTINGS

(1)Chemical analysis

(2)Tensile test(Tensile test at room temperature, Tensile test at elevated temperature)

(3)Flattening test

(4)Ring tensile test

(5)Drift expanding test

(6)Ring expanding test

(7)Impact test

(8)Leak tightness test(Hydrostatic test, Electromagnetic test)

(9)Dimensional inspection

(10) Visual examination

(11) Non-destructive testing

Note:

a The choice of flattening or ring tensile test and of drift expanding test or ring expanding test is at the manufacturer’s

discretion.

b For steel grades X10CrMoVNb9-1 tubes, the flattening or ring tensile test and the drift expanding test or ring expanding test shall be carried out at one end of 20 % of the tubes of each test unit.

c Group A: tubes having wall thickness T ≥ 16 mm manufactured from steel grades 1.4903 X10CrMoVNb9-1,

In the event that the purchaser does not indicate a wish to implement any of these options at the time of enquiry and order, the tubes shall be supplied in accordance with the basic specification

MARKING

Marking to be applied

The marking shall be indelibly marked on each tube at least at one end. For tubes with outside diameter D ≤ 51 mm the marking on tubes may be replaced by the marking on a label attached to the bundle or box.

EXAMPLE 100 m - Tube - d min 240 x T min 40 - EN 10216-2 1.4903 X10CrMoVNb9-1

Marking can be customized according to customer requirements

PROTECTION

The tubes will be delivered with A temporary protective coating or durable coating and/or lining

PHOTOS

![field:title/]](/uploads/220805/1-220P511543cX.jpg)

![field:title/]](/uploads/250212/1-250212142R1520.png)

![field:title/]](/uploads/230628/1-23062QK445208.jpg)

![field:title/]](/uploads/191012/1-19101215415K29.jpg)

![field:title/]](/uploads/191012/1-191012154122540.jpg)

![field:title/]](/uploads/220419/1-2204191914494F.png)

![field:title/]](/uploads/211026/1-2110261KF4F4.jpg)