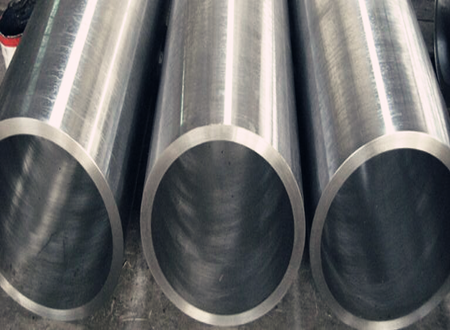

253MA(S30815)High-Temperature Stainless Steel Tubes

253MA (S30815) High-Temperature Stainless Steel Tubes

253MA is a heat-resistant pure austenitic stainless steel. With the scarcity of Ni and other resources and the continuous price, s30815 has the cost advantage of replacing 0Cr25Ni20, 0-4cr25ni20si2 series varieties.

At present, 253MA has been included in ASME standard, and its code is UNS s30815. The common boiler pipe standard SA213 and pressure vessel steel plate standard sa240 have corresponding regulations on 253MA material. 253MA (s30815) is a Ni type heat-resistant stainless steel, which is mainly used to manufacture boilers, superheaters, heat exchangers and pressure vessels and pipes for industrial equipment such as chemical industry, chemical fertilizer, petrochemical industry, etc.

253MA (S30815) high-temperature stainless steel tubes Quick Details

Type:seamless ,electric resistance welding process

Technique: Hot rolled or cold drawn

Standard:SA213, SA312

Outside Diameter :25mm-508mm

Wall thickness:6mm-22.8mm

Length:6000mm、12000m or specified length as required.

Type of End-Finish:Plain End、Beveled End、Treaded

Surface treatment: Tubes will be varnished (Outside only) to prevent rust.

Additional Info

Payment Terms:T / T, LC

Port of Shipment:Tianjin,China

Package:According To Per Customers' Require

Marking:Standard + Steel Grade + Size + Heat No + Lot No

Delivery time:Tubes will be completed within 30 days, and urgent delivery time can be discussed.

Heat Treatment

Solution Treatment (Annealing) Heat to 1050-1150°C and cool rapidly. It is recommended that the material be solution treated after 10-20% cold work to achieve maximum creep strength in service.

253MA (S30815) high-temperature stainless steel tube cannot be hardened by thermal treatment.

Manufacture

253MA (S30815) high-temperature stainless steel tubes are manufactured by seamless process or by electric resistance welding process

253MA (S30815) high-temperature Stainless steel tube is readily fabricated by standard commercial procedures. In comparison to carbon steel, stainless steels are tougher and tend to work harden rapidly. However, with positive feeds and slow speeds combined with abundant cutting fluid this alloys tendency to work harden may be minimized.

253MA (S30815) high-temperature Stainless steel tube can be welded using conventional welding processes. Filler metal should be of similar composition for maximum weld integrity and properties

Chemical Composition of 253MA (S30815) high-temperature stainless steel tubes , %

| Grade | Chemical Composition | ||||||||

| 253 MA | Cr | Ni | C | Si | Mn | P | S | N | Ce |

| 20.0-22.0 | 10.0-12.0 | 0.05-0.10 | 1.40-2.00 | 0.80max | 0.040max | 0.030max | 0.14-0.20 | 0.03-0.08 | |

Mechanical Properties Room Temperature

|

|

Specified Limits Minimum | Typical Range |

| Ultimate Tensile Strength, psi | 87,000 | 90,000-114,000 |

| .2% Offset Yield Strength, psi | 45,000 | 45,000-69,000 |

| Elongation in 2", % | 40 | 42-70 |

| Reduction of Area, % | 50 | - |

| Hardness Rockwell B | - | Rb 90 |

The chemical composition of the 253MA (S30815) high-temperature stainless steel tube is balanced, which makes the 253MA (S30815) stainless steel tube have the most suitable comprehensive performance in the temperature range of 850 °C-1100 °C, high oxidation resistance, and the scale temperature is up to 1150 °C; extremely high creep resistance Variability and creep rupture strength; good resistance to high temperature corrosion and resistance to brush corrosion in most gaseous media; high yield strength and tensile strength at high temperatures; good formability and Solderability and sufficient machinability.

In addition to the alloying elements chromium and nickel, the 253MA (S30815) high-temperature stainless steel tube also contains a small amount of rare earth metal, which significantly improves its antioxidant capacity. Nitrogen is added to improve creep properties and make this steel tube a complete austenite. Although the chromium and nickel contents are relatively low, this stainless steel tube has many of the same high temperature characteristics as the high alloyed alloy steel tube and the nickel base alloy steel tube.

Application:

253MA (S30815) high-temperature stainless steel tubes are widely used in sintering equipment, blast furnace equipment, steel melting, furnaces and continuous casting equipment, rolling mills (heating furnaces), heat treatment furnaces and accessories, mineral equipment and cement production equipment.

The 253MA (S30815) high-temperature stainless steel tube can be used at pressures up to 900 °C and non-pressured high temperature parts with operating temperatures up to 1150 °C.

Please fill the following form.

![field:title/]](/uploads/210625/1-210625161916213.jpg)

![field:title/]](/uploads/210820/1-210R0152411C1.jpg)

![field:title/]](/uploads/210731/1-210I11K610157.jpg)

![field:title/]](/uploads/200227/1-20022G02605963.jpg)

![field:title/]](/uploads/191012/1-191012155ZL36.png)

![field:title/]](/uploads/191012/1-191012155941221.png)

![field:title/]](/uploads/191012/1-191012160101521.png)