The microscopic world of stainless steel

How magical is the microscopic world? The beauty of stainless steel

As key materials in modern industry, the beauty of stainless steel and alloy materials is not only reflected in the macroscopic view, but also in the microscopic view. What we usually see most is the beauty of the appearance of the pipe, but under the microscopic view, the pipe also has a beautiful and moving heart. Today, let us appreciate the "beauty of stainless steel materials" together.

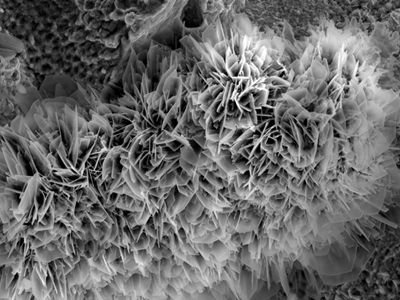

Art description: At the fracture of the stainless steel durable sample, the SEM technology was used to observe the lamellar oxide, like a cluster of flowers blooming on the edge of a cliff

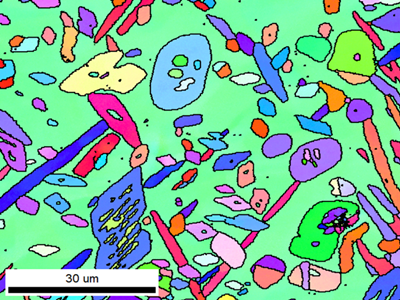

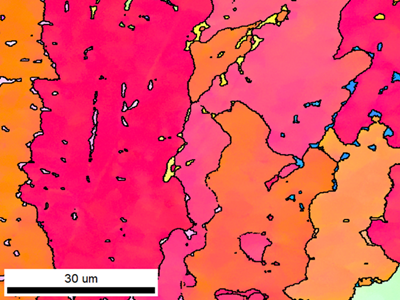

Art description: At the weld of the duplex steel, the EBSD technology was used to observe the irregular distribution of the duplex structure, in which the blocky austenite structure was like a tiny paramecium

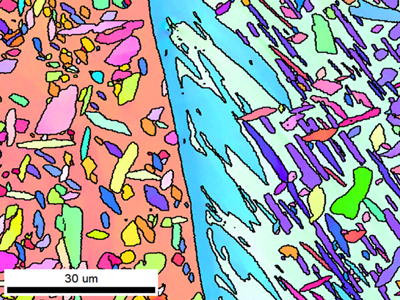

Art description: At the weld of the duplex steel, the EBSD technology was used to observe the irregular distribution of the duplex structure, and the different orientations of ferrite were divided into pink and blue, like the Chu River and Han River

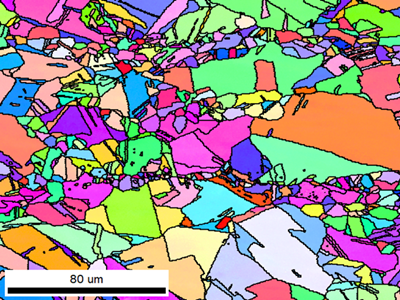

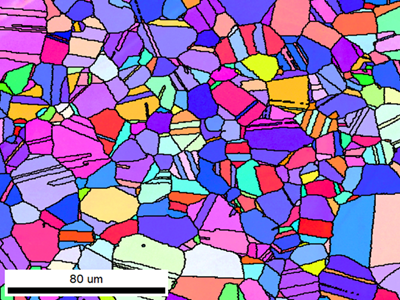

Art description: On the surface of stainless steel, the EBSD technology was used to observe the distribution of mixed crystal structure, and the areas of different colors were like fragments in a kaleidoscope, forming a constantly changing pattern during rotation

Art description :On the surface of stainless steel, EBSD technology is used to observe the distribution of grains and twin structures, just like the rainbow candy rain from the sky in childhood dreams, colorful

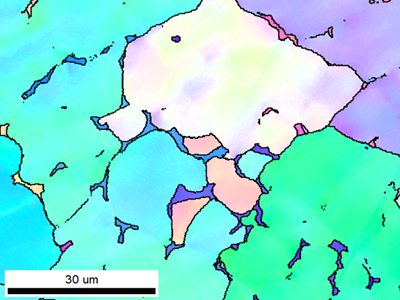

Artistic description: At the stainless steel weld, EBSD technology is used to observe the distribution of grain structure, just like the endless desert is dotted with oases

Artistic description: At the stainless steel weld, EBSD technology is used to observe the distribution of grain structure, just like a little white dog running happily on the grass

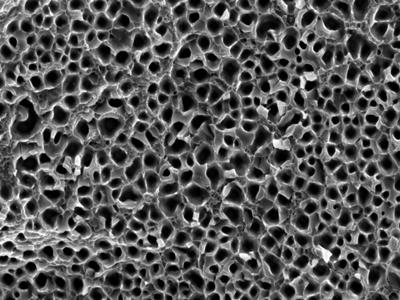

Artistic description: At the fracture of the stainless steel tensile specimen, SEM technology is used to observe the dense small dimple structure with a diameter of about 2μm, like a honeycomb

Artistic description: During the high-temperature in-situ stretching process of the stainless steel specimen, the to the cracking phenomenon along the grains, like dry and cracked land

Art description: After the surface of special stainless steel is etched, SEM technology is used to observe the second phase in a network distribution. The matrix is covered by the second phase and presents dark irregular pores, like a moon pit

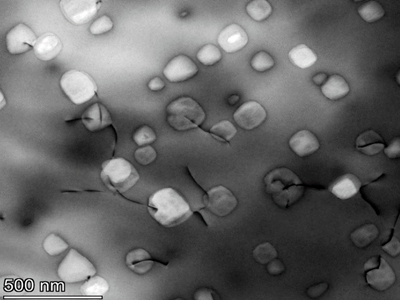

Art description: Transmission electron imaging technology is used to observe the interaction between nano-precipitated phases and dislocations in the material

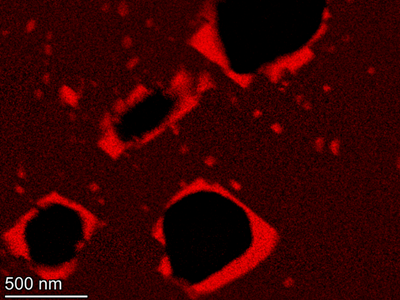

Art description: Characteristic X-ray detection technology is used to obtain the composition distribution map of chromium in a certain area in the material. The darker the red, the higher the chromium content

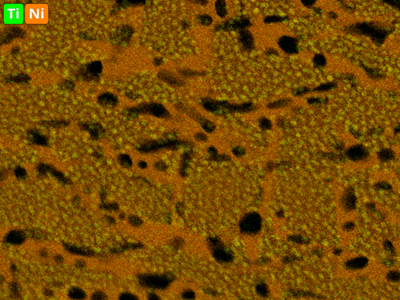

Art description: Characteristic X-ray detection technology is used to obtain the composition distribution map of titanium and nickel in a certain area in the material, where green represents titanium and yellow represents nickel

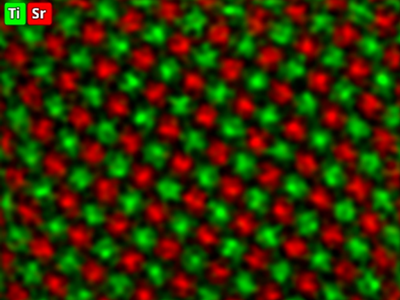

Artistic description: Nano electron beam scanning technology is used to detect the characteristic X-ray signal of a single atom to obtain the distribution map of the Ti and Sr atoms in the material

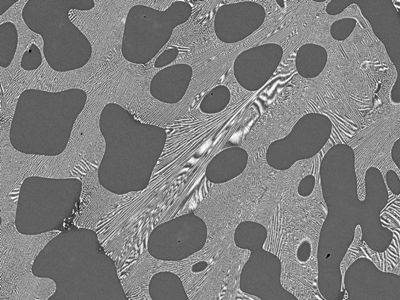

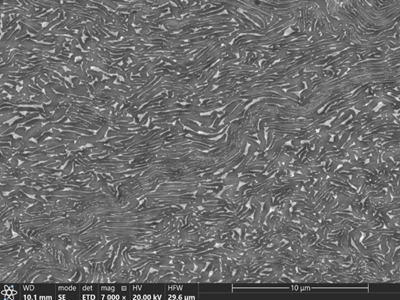

Artistic description: In alloy structural steel, the martensite layer eroded by metallographic corrosion presents a fish scale-like morphology according to different angles

Artistic description: The arrangement of two grains in a two-phase alloy, the white β phase is interspersed in the black α phase, forming a flowing water pattern

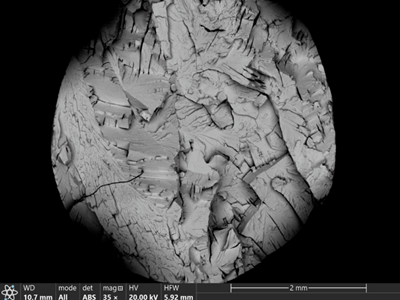

Artistic description: The morphology of cracking along the crystallographic plane formed on the tensile fracture of brittle fracture

The above are all "works" taken by colleagues at Beite Institute in their daily work. They left their own works, named and explained their works, which are really beautiful and dazzling. I hope everyone can create and discover those hidden beauties in their work, scientific research, and life. One day you will become the most beautiful scenery!

![field:title/]](/uploads/260123/1-260123164U23C.png)

![field:title/]](/uploads/251103/1-251103150340351.png)

![field:title/]](/uploads/250903/1-250Z3151641148.png)

![field:title/]](/uploads/250722/1-250H2145553S0.jpg)

![field:title/]](/uploads/250620/1-250620161459601.jpg)

![field:title/]](/uploads/250526/1-250526164100J8.png)

![field:title/]](/uploads/allimg/250306/1-250306152P2244-lp.png)

![field:title/]](/uploads/250207/1-25020G0333AH.png)