Treatment of bending deformation of steel pipe

Treatment of bending deformation of steel pipe

Abstract: A flame method to correct the bending deformation of a steel tube has been introduced in the thesis and has got satisfied effect.

introduction

In metal structure engineering, steel pipes are often used, and their dimensions are very important. Steel pipe

The quality of the body will directly affect the processing quality of the components, and even ultimately directly affect the overall project quality. However, in ordinary steel pipe procurement work, some steel pipes (especially larger diameter steel pipes) are often severely bent, but sometimes due to the pressure of construction period and other aspects, these steel pipes are still accepted, so it is necessary to The steel pipe is corrected as soon as possible.

1 Bending deformation analysis

It can be known from the principle of thermal processing deformation that during thermal processing (welding), the heating temperature varies

Uniformity, compression plastic deformation occurs in the high temperature zone, and the shrinkage of this part is prevented by other parts (low temperature zone or first cooling part) during cooling, resulting in residual stress and various deformations. In the steel market, hot-processed steel pipes (welded pipes or heat-expanded pipes) mainly exhibit bending deformation.

2 Treatment plan

When the diameter of the steel pipe is small and the pipe wall is relatively thick, the mechanical correction method (such as using plate rolling machine, jack and corresponding fixture) can be used to correct it, which is simple and easy to implement. However, when the diameter of the steel pipe is large and the pipe wall is relatively thin, the mechanical correction method is not suitable, because it not only requires huge mechanical equipment and complex fixtures, but also tends to cause partial depression of the steel pipe. However, the flame correction method is difficult to operate, but the method is simple and the effect is very good.

3 Examples of handling bending deformation

3.1 Introduction

In the second phase expansion project of *** power plant, our company ordered a batch of Ф630×8 heat-expanded steel pipes, made of Q235B, about 9m in length, and the bending heights are between 25~55mm, far exceeding the allowable deviation (L/ 1500, and should not be greater than 5.0mm), so the batch of steel pipes must be corrected.

3.2 Preparation

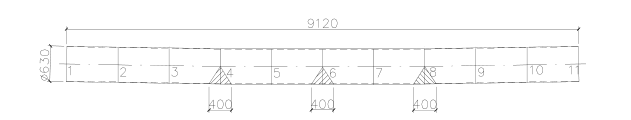

Take a steel pipe with a bending height of 55mm as an example, divide its length into 10 equal parts, and mark 11

Points (see Figure 1). The measured bending vector height of each point is shown in Table 1:

| Location | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|

Curved vector height (MM) |

0 | 16.5 | 30 | 42.5 | 51 | 55 | 52 | 41.5 | 32.5 | 14 | 0 |

3. 3 heat treatment

3. 3. 1 The heating zone is set according to the principle of heating deformation. The closer the heating zone is to the midpoint of the length of the steel pipe, the greater the bending deformation capacity. Conversely, the closer it is to both ends, the smaller the change. It is initially decided to arrange 3 heating zones, as shown in the shaded area in Figure 1. Choose 3 diamond heating zones (4, 6, 8) in the tension zone of the steel pipe, with a width of about 400mm, and mark them with white chalk.

3. 3. 2 Before heating, place the steel pipe on the platform steadily and balance the force. When heating, two people are responsible for the "6" heating zone at the same time, which is performed symmetrically in the radial direction of the steel pipe. Then each person is responsible for the "4" or "8" heating zone, extending from the center to both sides. The moving speed and temperature control of the welding torch of the two persons should be consistent. During the heating process, it is advisable to strictly control the heating temperature between 700 and 800°C. Because in this temperature zone, the metallographic structure basically does not change and has the ability of plastic deformation. In practice, the temperature is judged according to the color of the flame, and the general color is dark red to dark cherry red.

3. 3. 3 After the 3 heating parts have cooled down, measure the bending change of the steel pipe. If there is a small difference between the deformation data and the specifications, heating zones can be set at both ends. If the difference is large, reheat 5 and 7 again. After it cools down, measure the data until it meets the requirements.

3. 4 effect check

After multiple heating treatments, the bending height of the steel pipe has fully met the specification requirements. (See Table One and Table Two). Successfully solved the problem of steel pipe bending deformation, laying a solid foundation for the next step of steel component processing quality.

| Location | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|

Curved vector height (MM) |

0 | 1 | 2 | 2.5 | 3 | 3.5 | 3 | 2.5 | 1.5 | 0.5 | 0 |

3.5 Conclusion

Although the correction work has achieved complete success, in the future similar work, the following issues should be paid attention to: (1) When heating, do not rush for success. Each time the heating is completed, after it has cooled, the data should be measured and recorded to analyze the changes in the steel pipe to prevent overheating. (2) Avoid heating the same part multiple times to prevent damage to the mechanical properties of the material. (3) The heating zone should not be too wide, because when the heating is too wide, the result of first heating and first cooling will occur, which will reduce the thermoplastic compression deformation and make the correction effect worse.

Tube Bending

![field:title/]](/uploads/251210/1-251210164114F6.png)

![field:title/]](/uploads/241211/1-241211152454213.png)

![field:title/]](/uploads/220425/1-22042511053I30.jpg)

![field:title/]](/uploads/220414/1-220414214051492.jpg)

![field:title/]](/uploads/211104/1-211104121004V0.jpg)

![field:title/]](/uploads/211102/1-21110215254UP.jpg)

![field:title/]](/uploads/210923/1-2109231045325B.png)

![field:title/]](/uploads/200915/1-2009151K634949.jpg)