ASTM A192 ASME SA192 Finned Tube for Heat Exchanger

ASTM A192 ASME SA192 Finned Tube for Heat Exchanger

ASTM A192 Finned Tube is a heat exchange element. In order to improve the heat exchange efficiency, fins are usually added to the surface of the ASTM A192 seamless heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency.

ASTM A192,ASME SA192 High-Pressure Seamless Carbon Steel Boiler And Superheater Tubes sizes and thicknesses usually furnished to this specification are 1 ⁄ 2 in. to 7 in. [12.7 to 177.8 mm] outside diameter and 0.085 to 1.000 in. [2.2 to 25.4 mm], inclusive, in minimum wall thickness.

Types of ASTM A192 Finned Tube for Heat Exchanger

ASTM A192 L Type Finned Tube,

ASTM A192 LL Type Finned Tube,

ASTM A192 KL Type Finned Tube,

ASTM A192 G Type Finned Tube,

ASTM A192 H Type Finned Tube,

ASTM A192 Extruded Type Finned Tube,

ASTM A192 HF Finned Tube,

ASTM A192 Elliptical Finned Tube,

ASTM A192 Stud Finned Tube,

ASTM A192 Serrated Finned Tube,

ASTM A192 U Bending Low Finned Tube,

ASTM A192 Crimped Finned Tube,

ASTM A192 Inner Grooved Finned Tube,

ASTM A192 Longitudinal Finned Tube, etc.

ASTM A192 Finned Tube for Heat Exchanger Quick Details:

Core tube:ASTM A192,ASME SA192 cold-drawn seamless steel tube

Fin type: Solid plain

Fin Tube Type:L Type,LL Type,KL Type,G Type ,H Type ,Extruded Type ,HF,Elliptical Finned Tube,Stud Finned Tube,Serrated Finned Tube,U Bending ,Crimped Finned Tube,Inner Grooved Finned Tube,Longitudinal Finned Tube,etc.

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: 0.4mm~2mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

We can customize ASTM A192 Finned Tube for Heat Exchanger according to your drawings

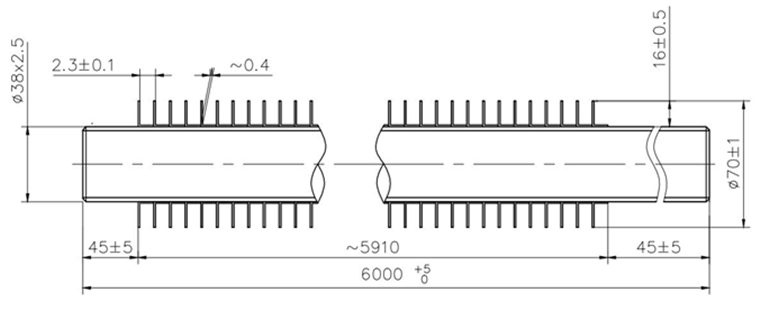

Example 1:

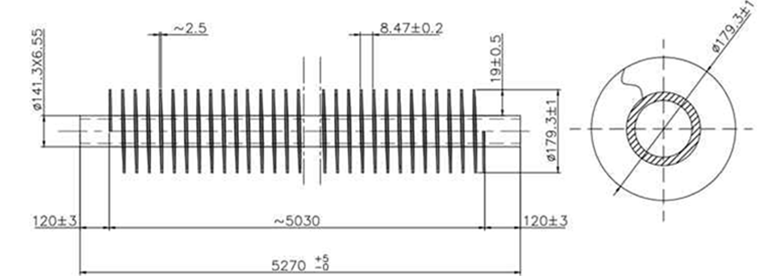

Example 2:

ASTM A192,ASME SA192 cold-drawn seamless steel tube Chemical Composition

| Carbon, % | 0.06–0.18 |

| Manganese, % | 0.27–0.63 |

| Phosphorus, max, % | 0.035 |

| Sulfur, max, % | 0.035 |

| Silicon, max, % | 0.25 |

| Tensile strength, min, ksi [MPa] | 47 [325] |

| Yield strength, min, ksi [MPa] | 26 [180] |

| Elongation in 2 in. or 50 mm, min, % | 35 |

| Brinell Hardness Number (Tubes 0.200 in. [5.1 mm] and over in wall thickness) | 137 HBW |

| Rockwell Hardness Number (Tubes less than 0.200 in.[5.1 mm] in wall thickness) | 77 HRBW |

Manufacturing Process of ASTM A192 Finned Tube

Fin strips (usually aluminum and copper) are folded into an L shape and wound under tension on the surface of the base tube. The feet of the fins are connected together and cover the surface of the fins.

ASTM A192 Finned Tube is combined with two different materials

Core tube material: A192

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Quality Control of ASTM A192 Finned Tube

Inspection and Tests Performed

Chemical Composition inspection,

Mechanical Properties Test(Tensile Strength, Yield Strength, Elongation, Flaring, Flattening, Hardness, Impact Test), S

surface and Dimension Test,

No-destructive Test,

Hydrostatic Test.

Delivery conditions

The tube ends are square cut without burrs, the inside is dry and blown clean, and the ends of the L-shaped tension wound finned tube are coated with varnish on the outside.

Acceptance Criteria

API Standard 661 (Air-Cooled Heat Exchangers for General Refinery Service) or Delivery Conditions (TDC).

Features of STM A192 Finned Tube for Heat Exchanger

1. Anti-corrosion

2. Anti-wear

2. lower contact resistance

4.Higher Stability

5. Anti-fouling ability

Application

1. Highly corrosive systems (condenser, evaporator, desalination, fertilization, urea system, ammonia, gas, corrosive acid);

2. Air coolers in petrochemical, electric power, paper, tobacco, building heating and other industries;

3. Air heaters and air heaters for spray drying systems such as vegetable protein powder and starch in the food industry;

4. Heat exchanger installations in power plants (electrical, nuclear, thermal and geothermal power plants).

Packaging of ASTM A192 Finned Tube

![field:title/]](/uploads/221102/1-221102151524U6.jpg)

![field:title/]](/uploads/191011/1-19101115123c01.jpg)