Urgent Customization of ASTM A179 U-Bend Tubes

Urgent Customization of ASTM A179 U-Bend Tubes

Small-batch urgent customization of thick-walled ASTM A179 U-Bend Tubes, tailored to customer needs.

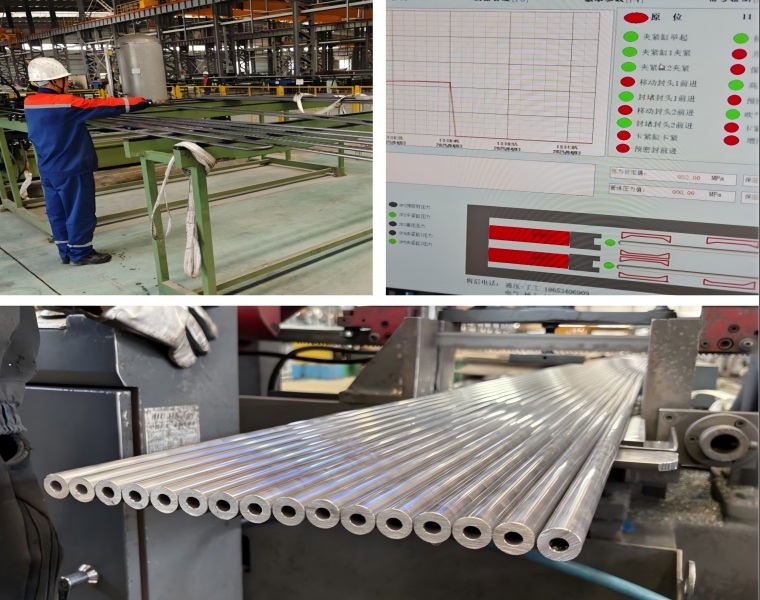

In mid-September, our company received an urgent purchase request from an equipment manufacturer for 40 U-Bend tubes due to maintenance on an energy circulation air cooler. These tubes conform to the ASTM A179 standard, are made of A179 material, and have specifications of 19 x 5 x L = 4400mm. Wall thickness tolerance is 0 to +0.5mm, and the minimum R° is 40mm. Each U-Bend tube must undergo a 52MPa/10s hydraulic pressure test. After completion, a 200mm blind area must be removed at each end. Delivery is only 20 days.

Given the order's small batch size (difficult heat treatment), small R° (R≈2D), small-diameter, ultra-thick wall (wall-to-outer-diameter ratio exceeding 0.28), and ultra-high pressure (52MPa), our company conducted a comprehensive assessment of the technical specifications, standard requirements, and equipment limitations. We carefully reviewed and confirmed every step, from the piercing and heat treatment process development, mold design, and finished product trial bending. Ultimately, we overcame the numerous difficulties of small-batch customization. The finished product's performance indicators and test results met the technical requirements, and the U Bend Tubes were successfully delivered within 20 days, saving the customer more time for equipment manufacturing.

![field:title/]](/uploads/251103/1-251103150340351.png)

![field:title/]](/uploads/250903/1-250Z3151641148.png)

![field:title/]](/uploads/250722/1-250H2145553S0.jpg)

![field:title/]](/uploads/250620/1-250620161459601.jpg)

![field:title/]](/uploads/250526/1-250526164100J8.png)

![field:title/]](/uploads/allimg/250306/1-250306152P2244-lp.png)

![field:title/]](/uploads/250207/1-25020G0333AH.png)

![field:title/]](/uploads/250114/1-25011412060W35.jpg)