ASTM A1016 ASME SA1016 Standard

ASTM A1016/A1016M

Standard Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

1. Scope

1.1 This specification covers a group of requirements that,unless otherwise specified in an individual specification, shall apply to the ASTM product specifications noted below.

| Title of Specification | ASTM Designation A |

| Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes | A209/A209M |

| Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater,and Heat-Exchanger Tubes | A213/A213M |

| Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger,and Condenser Tubes | A249/A249M |

| Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater Tubes | A250/A250M |

| Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service | A268/A268M |

| Seamless and Welded Austenitic Stainless Steel Tubing for General Service | A269 |

| Seamless and Welded Austenitic Stainless Steel Sanitary Tubing | A270 |

| Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service | A334/A334M |

| Welded Austenitic Stainless Steel Feedwater Heater Tubes | A668/A668M |

| Austenitic Stainless Steel Tubing for Breeder Reactor Core Components | A771/A771M |

| Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service | A789/A789M |

| Welded Ferritic Stainless Steel Feedwater Heater Tubes | A803/A803M |

| Austenitic and Ferritic Stainless Steel Duct Tubes for Breeder Reactor Core Components | A826/A826M |

| High-Frequency Induction Welded, Unannealed Austenitic Steel Condenser Tubes | A851 |

A These designations refer to the latest issue of the respective specifications.

1.2 In the case of conflict between a requirement of a product specification and a requirement of this general requirements specification, the product specification shall prevail. In the case of conflict between a requirement of the product specification or a requirement of this general requirements specification and a more stringent requirement of the purchase order, the purchase order shall prevail.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M”designation (SI) of the product specification is specified in the order.

2. Referenced Documents

2.1 ASTM Standards:

A209/A209M Specification for Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes

A213/A213M Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

A249/A249M Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

A250/A250M Specification for Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater Tubes

A268/A268M Specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service

A269 Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

A270 Specification for Seamless and WeldedAustenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing

A334/A334M Specification for Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A530/A530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

A668/A668M Specification for Steel Forgings, Carbon and Alloy, for General Industrial Use

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A771/A771M Specification for Seamless Austenitic and Martensitic Stainless Steel Tubing for Liquid Metal-Cooled Reactor Core Components

A789/A789M Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service

A803/A803M Specification for Welded Ferritic Stainless Steel Feedwater Heater Tubes

A826/A826M Specification for Seamless Austenitic and Martensitic Stainless Steel Duct Tubes for Liquid Metal-Cooled Reactor Core Components

A851 Specification for High-Frequency Induction Welded,Unannealed, Austenitic Steel Condenser Tubes

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A1047/A1047M Test Method for Pneumatic Leak Testing of Tubing

D3951 Practice for Commercial Packaging

E92 Test Method for Vickers Hardness of Metallic Materials

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E273 Practice for Ultrasonic Examination of the Weld Zone of Welded Pipe and Tubing

E309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

E426 Practice for Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar Alloys

E570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

2.2 ASME Boiler and Pressure Vessel Code:

Section IX, Welding Qualifications

2.3 Federal Standard:

FED-STD-183 Continuous Identification Marking of Iron and Steel Products

2.4 Military Standards:

MIL-STD-271 Nondestructive Testing Requirements for Metals

MIL-STD-163 Steel Mill Products Preparation for Shipment and Storage

MIL-STD-792 Identification Marking Requirements for Special Purpose Equipment

2.5 Steel Structures Painting Council:

SSPC-SP6 Surface Preparation Specification No.6 Commercial Blast Cleaning

2.6 Other Documents:

SNT-TC-1A Recommended Practice for Nondestructive Personnel Qualification and Certification

AIAG Bar Code Symbology Standard

3. Terminology

3.1 Definitions:

3.1.1 The definitions in Test Methods and Definitions A370,Test Methods, Practices, and Terminology A751, and Terminology A941 are applicable to this specification and to those listed in 1.1.

3.1.2 heat, n—in secondary melting, all of the ingots remelted from a single primary heat.

3.1.3 imperfection, n—any discontinuity or irregularity found in a tube.

4. Manufacture

4.1 The steel shall made by any process.

4.2 The primary melting is permitted to incorporate separate degassing or refining and is permitted to be followed by secondary melting, such as electroslag remelting or vacuumarc remelting.

4.3 When steel of different grades is sequentially strand cast, the resultant transition material shall be removed using an established procedure that positively separates the grades.

5. Ordering Information

5.1 It is the responsibility of the purchaser to specify all requirements that are necessary for product ordered under the product specification. Such requirements to be considered include, but are not limited to, the following:

5.1.1 Quantity (feet, metres, or number of pieces),

5.1.2 Name of material (stainless steel tubing),

5.1.3 Method of manufacture, when applicable (seamless(SML), welded (WLD), or heavily cold-worked (HCW)),

5.1.4 Grade or UNS number,

5.1.5 Size (outside diameter and average or minimum wall thickness),

5.1.6 Length (specific or random),

5.1.7 End finish if required,

5.1.8 Optional requirements,

5.1.9 Specific type of melting, if required,

5.1.10 Test report requirements,

5.1.11 Specification designation and year of issue, and

5.1.12 Special requirements or any supplementary requirements, or both.

6. Chemical Composition

6.1 Chemical Analysis—Samples for chemical analysis, and method of analysis, shall be in accordance with Test Methods,Practices, and Terminology A751.

6.2 Heat Analysis—An analysis of each heat of steel shall be made by the steel manufacturer to determine the percentages of the elements specified. If secondary melting processes are employed, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The chemical composition thus determined, or that determined from a product analysis made by the tubular product manufacturer, shall conform to the requirements specified in the product specification.

6.2.1 For steels ordered under product specifications referencing this specification of general requirements, the steel shall not contain an unspecified element, other than nitrogen for stainless steels, for the ordered grade to the extent that the steel conforms to the requirements of another grade for which that element is a specified element having a required minimum content. For this requirement, a grade is defined as an alloy described individually and identified by its own UNS designation in a table of chemical requirements within any specification listed within the scope as being covered by this specification.

6.3 Product Analysis—Product analysis requirements and options, if any, shall be as contained in the product specification.

7. Tensile Properties

7.1 The material shall conform to the tensile property requirements prescribed in the individual product specification.

7.2 The yield strength, when specified, shall be determined corresponding to a permanent offset of 0.2 % of the gage length or to a total extension of 0.5 % of the gage length under load.

7.3 If the percentage of elongation of any test specimen is less than that specified and any part of the fracture is more than 3 ⁄ 4 in. [19.0 mm] from the center of the gage length, as indicated by scribe marks on the specimen before testing, a retest shall be allowed.

8. Standard Mass per Unit Length

8.1 The calculated mass per foot, based upon a specified minimum wall thickness, shall be determined by the following equation (see Note 1):

W = C (D-t) t (1)

where:

C = 10.69 [0.0246615],

W = mass per unit length, lb/ft [kg/m],

D = specified outside diameter, in. [mm], and

t = specified minimum wall thickness, in. [mm].

NOTE 1—The calculated masses given by Eq 1 are based on the masses for carbon steel tubing. The mass of tubing made of ferritic stainless steels may be up to about 5 % less, and that made of austenitic stainless steel up to about 2 % greater than the values given. Mass of ferritic/austenitic (duplex) stainless steel will be intermediate to the mass of fully austenitic and fully ferritic stainless steel tubing.

8.2 The permitted variations from the calculated mass per foot [kilogram per meter] shall be as prescribed in Table 1.

TABLE 1 Permitted Variations in Mass Per Foot A

| Method of Manufacture | Permitted Variation in Mass per Foot, % | |

| Over | Under | |

| Seamless, hot-finished | 16 | 0 |

| Seamless, cold-finished | ||

| 1 1 ⁄ 2 in. [38 mm] and under OD | 12 | 0 |

| Over 1 1 ⁄ 2 in. [38 mm] OD | 13 | 0 |

| Welded | 10 | 0 |

A These permitted variations in mass apply to lots of 50 tubes or more in sizes 4 in. [101.6 mm] and under in outside diameter, and to lots of 20 tubes or more in sizes over 4 in. [101.6 mm] in outside diameter.

9. Permitted Variations in Wall Thickness

9.1 Variations from the specified minimum wall thickness shall not exceed the amounts prescribed in Table 2.

TABLE 2 Permitted Variations in Wall Thickness A

|

Wall Thickness, %

|

||||||||

|

Outside Diameter in. [mm] |

0.095 [2.4] and Under |

Over 0.095 to 0.150 [2.4 to 3.8], incl |

Over 0.150 to 0.0180 [3.8 to 4.6], incl |

Over 0.180 [4.6] | ||||

| Over | Under | Over | Under | Over | Under | Over | Under | |

| Seamless, Hot-Finished Tubes | ||||||||

|

4 [100] and under |

40 | 0 | 35 | 0 | 33 | 0 | 28 | 0 |

| Over 4 [100] | .... | .... | 35 | 0 | 33 | 0 | 28 | 0 |

| Seamless, Cold-Finished Tubes | ||||||||

| Over | Under | |||||||

| 1 1 ⁄ 2 [38.1] and under | 20 | 0 | ||||||

| Over 1 1 ⁄ 2 [38.1] | 22 | 0 | ||||||

| Welded Tubes | ||||||||

| All sizes | 18 | 0 | ||||||

A These permitted variations in wall thickness apply only to tubes, except internal-upset tubes, as rolled or cold-finished, and before swaging, expanding,bending, polishing, or other fabricating operations.

9.2 For tubes 2 in. [50 mm] and over in outside diameter and 0.220 in. [5.6 mm] and over in thickness, the variation in wall thickness in any one cross section of any one tube shall not exceed the following percentage of the actual mean wall at the section. The actual mean wall is defined as the average of the thickest and thinnest wall in that section.

Seamless tubes 610 %

Welded tubes 65 %

Welded tubes 65 %

9.3 When cold-finished tubes as ordered require wall thicknesses 3 ⁄ 4 in. [19.1 mm] or over, or an inside diameter 60 % or less of the outside diameter, the permitted variations in wall thickness for hot-finished tubes shall apply.

10. Permitted Variations in Outside Diameter

10.1 Except as provided in 10.2.1, 10.3, and 25.10.4,variations from the specified outside diameter shall not exceed the amounts prescribed in Table 3.

TABLE 3 Permitted Variations in Outside Diameter A

| Specified Outside Diameter,in. [mm] | Permitted Variations, in. [mm] | |

| Over | Under | |

| Hot-Finished Seamless Tubes | ||

| 4 [100] or under | 1 ⁄ 64 [0.4] | 1 ⁄ 32 [0.8] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 1 ⁄ 64 [0.4] | 3 ⁄ 64 [1.2] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 1 ⁄ 64 [0.4] | 1 ⁄ 16 [1.6] |

| Welded Tubes and Cold-Finished Seamless Tubes | ||

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 1 1 ⁄ 2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 1 1 ⁄ 2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 2 1 ⁄ 2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 2 1 ⁄ 2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 7 1 ⁄ 2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 7 1 ⁄ 2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

A Except as provided in 10.2 and 10.3, these permitted variations include out-of-roundness. These permitted variations in outside diameter apply to hot-finished seamless, welded and cold-finished seamless tubes before other fabri-cating operations such as upsetting, swaging, expanding, bending, or polishing.

10.2 Thin-wall tubes usually develop significant ovality (out-of-roundness) during final annealing, or straightening, or both. Thin-wall tubes are defined as those with a specified wall 3 % or less than the specified OD, or with a wall specified as 0.020 in. [0.5 mm] or less.

10.2.1 1 The diameter tolerances of Table 3 are not sufficient to provide for additional ovality expected in thin-wall tubes,and, for such tubes, are applicable only to the mean of the extreme (maximum and minimum) outside diameter readings in any one cross section. However, for thin wall tubes the difference in extreme outside diameter readings (ovality) in any one cross section shall not exceed the following ovality allowances:

| Outside Diameter, in. [mm] | Ovality Allowance |

| 1 [25.4] and under | 0.020 [0.5] |

| Over 1 [25.4] | 2.0 % of specified outside diameter |

10.3 For cold-finished seamless austenitic and ferritic/austenitic tubes, an ovality allowance is necessary for all sizes less than 2 in. [50.8 mm] outside diameter, because they are likely to become out of round during their final heat treatment.For such tubes, the maximum and minimum outside diameter at any cross section shall not deviate from the nominal diameter by more than 60.010 in. [60.25 mm]. However, the mean diameter at that cross section must still be within the given permitted variation given in Table 3. In the event of conflict between the provisions of 10.2.1 and those of 10.3, the larger value of ovality tolerance shall apply.

10.4 When the specified wall is 2 % or less of the specified OD, the method of measurement is per agreement between purchaser and manufacturer (see Note 2).

NOTE 2—Very thin wall tubing may not be stiff enough for the outside diameter to be accurately measured with a point contact method, such as with the use of a micrometer or caliper. When very thin walls are specified, “go” – “no go” ring gages are commonly used to measure diameters of 1 1 ⁄ 2 in. [38.1 mm] or less. A .002 in. [0.05 mm] additional tolerance is usually added on the “go” ring gage to allow clearance for sliding. On larger diameters, measurement is commonly performed with a pi tape. Other methods, such as optical methods, may also be considered.

11. Permitted Variations in Length

11.1 Variations from the specified length shall not exceed the amounts prescribed in Table 4.

TABLE 4 Permitted Variations in Length A

|

Method of Manufacture |

Specified Outside Diameter, in.[mm] |

Cut Length, in. [mm] | |

| Over | Under | ||

| Seamless, hot-finished | All sizes | 3 ⁄ 16 [5] | 0 [0] |

| Seamless, cold-finished | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

| Welded | Under 2 [50.8] | 1 ⁄ 8 [3] | 0 [0] |

| 2 [50.8] or over | 3 ⁄ 16 [5] | 0 [0] | |

A These permitted variations in length apply to tubes before bending. They apply to cut lengths up to and including 24 ft [7.3 m]. For lengths greater than 24 ft [7.3m], the above over-tolerances shall be increased by 1 ⁄ 8 in. [3 mm] for each 10 ft [3m] or fraction thereof over 24 ft or 1 ⁄ 2 in. [13 mm], whichever is the lesser.

12. Permitted Variations in Height of Flash on Electric-Resistance-Welded Tubes

12.1 For tubes over 2 in. [50.8 mm] in outside diameter, or over 0.135 in. [3.44 mm] in wall thickness, the flash on the inside of the tubes shall be mechanically removed by cutting to a maximum height of 0.010 in. [0.25 mm] at any point on the tube.

12.2 For tubes 2 in. [50.8 mm] and under in outside diameter and 0.135 in. [3.44 mm] and under in wall thickness,the flash on the inside of the tube shall be mechanically removed by cutting to a maximum height of 0.006 in. [0.15mm] at any point on the tube.

13. Straightness and Finish

13.1 Finished tubes shall be reasonably straight and have smooth ends free of burrs. They shall have a workmanlike finish. It is permitted to remove surface imperfections by grinding, provided that a smooth curved surface is maintained,and the wall thickness is not decreased to less than that permitted by this or the product specification, or the purchase order. The outside diameter at the point of grinding may be reduced by the amount so removed.

14. Repair by Welding

14.1 Repair welding of base metal defects in tubing is permitted only with the approval of the purchaser and with the further understanding that the tube shall be marked “WR” and the composition of the deposited filler metal shall be suitable for the composition being welded. Defects shall be thoroughly chipped or ground out before welding and each repaired length shall be reheat treated or stress relieved as required by the applicable specification. Each length of repaired tube shall be examined by a nondestructive test as required by the product specification.

14.2 Repair welding shall be performed using procedures and welders or welding operators that have been qualified in accordance with ASME Boiler and Pressure Vessel Code,Section IX.

15. Retests

15.1 If the results of the mechanical tests of any group or lot do not conform to the requirements specified in the individual specification, retests may be made on additional tubes of double the original number from the same group or lot, each of which shall conform to the requirements specified.

16. Reheat Treatment

16.1 If the individual tubes or the tubes selected to represent any group or lot fail to conform to the test requirements, the individual tubes or the group or lot represented may be reheat treated and resubmitted for test. Not more than two reheat treatments shall be permitted.

17. Test Specimens

17.1 Test specimens shall be taken from the ends of finished tubes prior to upsetting, swaging, expanding, or other forming operations, or being cut to length. They shall be smooth on the ends and free of burrs and flaws.

17.2 If any test specimen shows flaws or defective machining, it may be discarded and another specimen substituted.

18. Method of Mechanical Testing

18.1 The specimens and mechanical tests required shall be made in accordance with Test Methods and Definitions A370.

18.2 Specimens shall be tested at room temperature.

18.3 Small or subsize specimens as described in Test Methods and DefinitionsA370 may be used only when there is insufficient material to prepare one of the standard specimens.When using small or subsize specimens, the largest one possible shall be used.

19. Flattening Test

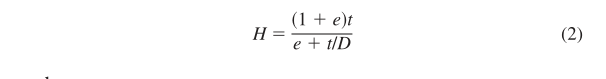

19.1 A section of tube not less than 2 1 ⁄ 2 in. [60 mm] in length for seamless tubes and not less than 4 in. [100 mm] in length for welded tubes and for heavily cold-worked tubes shall be flattened cold between parallel plates in two steps. For welded tubes, the weld shall be placed 90° from the direction of the applied force (at a point of maximum bending). During the first step, which is a test for ductility, no cracks or breaks,except as provided for in 19.4, on the inside, outside, or end surfaces shall occur in seamless tubes, or on the inside or outside surfaces of welded tubes and heavily cold-worked tubes, until the distance between the plates is less than the value of H calculated by the following equation:

where:

H = distance between flattening plates, in. [mm],

t = specified wall thickness of the tube, in. [mm],

D = specified outside diameter of the tube, in. [mm], and

e = deformation per unit length (constant for a given grade of steel: 0.07 for medium-carbon steel (maximum specified carbon 0.19 % or greater), 0.08 for ferritic alloy steel, 0.09 for austenitic steel, and 0.09 for low-carbon steel (maximum specified carbon 0.18 % or less).

During the second step, which is a test for soundness, the flattening shall be continued until the specimen breaks or the opposite walls of the specimen meet. Evidence of laminated or unsound material, or of incomplete weld that is revealed during the entire flattening test shall be cause for rejection.

19.2 Surface imperfections in the test specimens before flattening, but revealed during the first step of the flattening test, shall be judged in accordance with the finish requirements.

19.3 Superficial ruptures resulting from surface imperfections shall not be cause for rejection.

19.4 When low D-to-t ratio tubular products are tested,because the strain imposed due to geometry is unreasonably high on the inside surface at the six and twelve o’clock locations, cracks at these locations shall not be cause for rejection if the D-to-t ratio is less than 10.

20. Reverse Flattening Test

20.1 A section 4 in. [100 mm] in length of finished welded tubing in sizes down to and including 1 ⁄ 2 in. [12.7 mm] in outside diameter shall be split longitudinally 90° on each side of the weld and the sample opened and flattened with the weld at the point of maximum bend. There shall be no evidence of cracks or lack of penetration or overlaps resulting from flash removal in the weld.

21. Reverse Bend Test

21.1 A section 4 in. [100 mm] minimum in length shall be split longitudinally 90° on each side of the weld. The sample shall then be opened and bent around a mandrel with a maximum thickness of four times the wall thickness, with the mandrel parallel to the weld and against the original outside surface of the tube. The weld shall be at the point of maximum bend. There shall be no evidence of cracks or of overlaps resulting from the reduction in thickness of the weld area by cold working. When the geometry or size of the tubing make it difficult to test the sample as a single piece, the sample may be sectioned into smaller pieces provided a minimum of 4 in. of weld is subjected to reverse bending.

21.2 The reverse bend test is not applicable when the wall is 10 % or more of the specified outside diameter, or the wall thickness is 0.134 in. [3.4 mm] or greater, or the outside diameter is less than 0.375 in. [9.5 mm]. Under these conditions, the reverse flattening test shall apply.

22. Flaring Test

22.1 A section of tube approximately 4 in. [100 mm] in length shall stand being flared with a tool having a 60° included angle until the tube at the mouth of the flare has been expanded to the percentages specified in Table 5 without cracking or showing imperfections rejectable under the provisions of the product specification.

TABLE 5 Flaring Test Requirements

|

Ratio of Inside Diameter to Specified Outside Diameter A |

Minimum Expansion of Inside Diameter, % | |

|

Carbon, Carbon-Molybdenum, and Other Ferritic Alloy Steels |

Austenitic Steels | |

| 0.9 | 21 | 15 |

| 0.8 | 22 | 17 |

| 0.7 | 25 | 19 |

| 0.6 | 30 | 23 |

| 0.5 | 39 | 28 |

| 0.4 | 51 | 38 |

| 0.3 | 68 | 50 |

A In determining the ratio of inside diameter to specified outside diameter, the inside diameter shall be defined as the actual mean inside diameter of the material tested.

23. Flange Test

23.1 A section of tube shall be capable of having a flange turned over at a right angle to the body of the tube without cracking or showing imperfections rejectable under the provisions of the product specification. The width of the flange for carbon and alloy steels shall be not less than the percentages specified in Table 6. For the austenitic grades, the width of the flange for all sizes listed in Table 6 shall be not less than 15 %.

TABLE 6 Flange Requirements

| Specified Outside Diameter of Tube, in. [mm] | Width of Flange |

| To 2 1 ⁄ 2 [63.5], incl | 15 % of Specified Outside Diameter |

| Over 2 1 ⁄ 2 to 3 3 ⁄ 4 [63.5 to 95.2], incl | 12 1 ⁄ 2 % of Specified Outside Diameter |

| Over 3 3 ⁄ 4 to 8 [95.2 to 203.2], incl | 10 % of Specified Outside Diameter |

24. Hardness Test

24.1 For tubes with wall thickness 0.200 in. [5.1 mm] or over, either the Brinell or Rockwell hardness test shall be used.When Brinell hardness testing is used, a 10-mm ball with 3000,1500, or 500-kg load, or a 5-mm ball with 750-kg load shall be used, at the option of the manufacturer.

24.2 For tubes with wall thickness 0.065 in. [1.7 mm] or over but less than 0.200 in. [5.1 mm], the Rockwell hardness test shall be used.

24.3 For tubes with wall thickness less than 0.065 in. [1.7mm], the hardness test shall not be required.

24.4 The Brinell hardness test shall, at the option of the manufacturer, be made on the outside of the tube near the end,on the outside of a specimen cut from the tube, or on the wall cross section of a specimen cut from the tube. This test shall be made so that the distance from the center of the impression to the edge of the specimen is at least 2.5 times the diameter of the impression.

24.5 The Rockwell hardness test shall, at the option of the manufacturer, be made on the inside surface, on the wall cross section, or on a flat on the outside surface.

24.6 For tubes furnished with upset, swaged, or otherwise formed ends, the hardness test shall be made as prescribed in 24.1 and 24.2 on the outside of the tube near the end after the forming operation and heat treatment.

24.7 For welded or brazed tubes, the hardness test shall be made away from the joints.

24.8 When the product specification provides for Vickers hardness, such testing shall be in accordance with Test Method E92.

25. Nondestructive Examination

25.1 Except as provided in 26.1, each tube shall be examined by a nondestructive examination method in accordance with Practice E213, Practice E309 (for ferromagnetic materials), Practice E426 (for non-magnetic materials), or Practice E570. Upon agreement, Practice E273 shall be employed in addition to one of the full periphery tests. The range of tube sizes that may be examined by each method shall be subject to the limitations in the scope of that practice. In case of conflict between these methods and practices and this specification, the requirements of this specification shall prevail.

25.2 The following information is for the benefit of the user of this specification.

25.2.1 Calibration standards for the nondestructive electric test are convenient standards for calibration of nondestructive testing equipment only. For several reasons, including shape,orientation, width, and so forth, the correlation between the signal produced in the electric test from an imperfection and from calibration standards is only approximate. A purchaser interested in ascertaining the nature (type, size, location, and orientation) of discontinuities that can be detected in the specific application of these examinations should discuss this with the manufacturer of the tubular product.

25.2.2 The ultrasonic examination referred to in this specification is intended to detect longitudinal discontinuities having a reflective area similar to or larger than the calibration reference notches specified in 25.8. The examination may not detect circumferentially oriented imperfections or short, deep defects.

25.2.3 The eddy current examination referenced in this specification has the capability of detecting significant discontinuities, especially of the short abrupt type. Practices E309 and E426 contain additional information regarding the capabilities and limitations of eddy-current examination.

25.2.4 The flux leakage examination referred to in this specification is capable of detecting the presence and location of significant longitudinally or transversely oriented discontinuities. The provisions of this specification only provide for longitudinal calibration for flux leakage. It should be recognized that different techniques should be employed to detect differently oriented imperfections.

25.2.5 The hydrostatic test referred to in Section 25 is a test method provided for in many product specifications. This test has the capability of finding defects of a size permitting the test fluid to leak through the tube wall and may be either visually seen or detected by a loss of pressure. This test may not detect very tight, through-the-wall defects or defects that extend an appreciable distance into the wall without complete penetration.

25.2.6 A purchaser interested in ascertaining the nature (type, size, location, and orientation) of discontinuities that can be detected in the specific application of these examinations should discuss this with the manufacturer of the tubular products.

25.3 Time of Examination—Nondestructive examination for specification acceptance shall be performed after all deformation processing, heat treating, welding, and straightening operations. This requirement does not preclude additional testing at earlier stages in the processing.

25.4 Surface Condition:

25.4.1 All surfaces shall be free of scale, dirt, grease, paint,or other foreign material that could interfere with interpretation of test results. The methods used for cleaning and preparing the surfaces for examination shall not be detrimental to the base metal or the surface finish.

25.4.2 Excessive surface roughness or deep scratches can produce signals that interfere with the test.

25.5 Extent of Examination:

25.5.1 The relative motion of the tube and the transducer(s),coil(s), or sensor(s) shall be such that the entire tube surface is scanned, except for end effects as noted in 25.5.2.

25.5.2 The existence of end effects is recognized, and the extent of such effects shall be determined by the manufacturer,and, if requested, shall be reported to the purchaser. Other nondestructive tests may be applied to the end areas, subject to agreement between the purchaser and the manufacturer.

25.6 Operator Qualifications:

25.6.1 The test unit operator shall be certified in accordance with SNT-TC-1A, or an equivalent documented standard agreeable to both purchaser and manufacturer.

25.7 Test Conditions:

25.7.1 For examination by the ultrasonic method, the minimum nominal transducer frequency shall be 2.0 MHz, and the maximum transducer size shall be 1.5 in. [38 mm].

25.7.2 For eddy current testing, the excitation coil frequency shall be chosen to ensure adequate penetration, yet provide good signal-to-noise ratio.

25.7.2.1 The maximum coil frequency shall be:

| Specified Wall Thickness, in. [mm] | Maximum Frequency, kHz |

| <0.050 in. [1.25] | 100 |

| 0.050 to 0.150 [1.25 to 3.80] | 50 |

| >0.150 [3.80] | 10 |

25.8 Reference Standards:

25.8.1 Reference standards of convenient length shall be prepared from a length of tube of the same grade, specified size (outside diameter and wall thickness), surface finish, and heat treatment condition as the tubing to be examined.

25.8.2 For eddy current testing, the reference standard shall contain, at the option of the manufacturer, any one of the following discontinuities:

25.8.2.1 Drilled Hole—The reference standard shall contain three or more holes, equally spaced circumferentially around the tube and longitudinally separated by a sufficient distance to allow distinct identification of the signal from each hole. The holes shall be drilled radially and completely through the tube wall, with care being taken to avoid distortion of the tube while drilling. The holes shall not be larger than 0.031 in. [0.8 mm] in diameter.As an alternative, the producer may choose to drill one hole and run the calibration standard through the test coil three times, rotating the tube approximately 120° each time.More passes with smaller angular increments may be used,provided testing of the full 360° of the coil is obtained. For welded tubing, if the weld is visible, one of the multiple holes or the single hole shall be drilled in the weld.

25.8.2.2 Transverse Tangential Notch—Using a round tool or file with a 1 ⁄ 4 in. [6.4 mm] diameter, a notch shall be milled or filed tangential to the surface and transverse to the longitudinal axis of the tube. Said notch shall have a depth not exceeding 12.5 % of the specified wall thickness of the tube or 0.004 in. [0.1 mm], whichever is greater.

25.8.2.3 Longitudinal Notch—A notch 0.031 in. (0.8 mm) or less in width shall be machined in a radial plane parallel to the tube axis on the outside surface of the tube, to have a depth not exceeding 12.5 % of the specified wall thickness of the tube or 0.004 in. (0.1 mm), whichever is greater. The length of the notch shall be compatible with the testing method.

25.8.3 For ultrasonic testing, the reference ID and OD notches shall be any one of the three common notch shapes shown in Practice E213, at the option of the manufacturer. The depth of the notches shall not exceed 12.5 % of the specified wall thickness of the tube or 0.004 in. [0.1 mm], whichever is greater. The width of the notch shall not exceed two times the depth. For welded tubing, the notches shall be placed in the weld, if the weld is visible.

25.8.4 For flux leakage testing, the longitudinal reference notches shall be straight-sided notches machined in a radial plane parallel to the tube axis on the inside and outside surfaces of the tube. Notch depth shall not exceed 12.5 % of the specified wall thickness or 0.004 in. [0.1 mm], whichever is greater. Notch length shall not exceed 1 in. [25.4 mm], and the width shall not exceed the depth. Outside and inside notches shall have sufficient separation to allow distinct identification of the signal from each notch.

25.8.5 More or smaller reference discontinuities, or both,may be used by agreement between the purchaser and the manufacturer.

25.9 Standardization Procedure:

25.9.1 The test apparatus shall be standardized at the beginning and end of each series of tubes of the same specified size (diameter and wall thickness), grade and heat treatment condition, and at intervals not exceeding 4 h during the examination of such tubing. More frequent standardizations may be performed at the manufacturer’s option or may be required upon agreement between the purchaser and the manufacturer.

25.9.2 The test apparatus shall also be standardized after any change in test system settings, change of operator, equipment repair, or interruption due to power loss or shutdown.

25.9.3 The reference standard shall be passed through the test apparatus at the same speed and test system settings as the tube to be tested, except that, at the manufacturer’s discretion,the tubes may be tested at a higher sensitivity.

25.9.4 The signal-to-noise ratio for the reference standard shall be 2.5:1 or greater, and the reference signal amplitude for each discontinuity shall be at least 50 % of full scale of the display. In establishing the noise level, extraneous signals from identifiable surface imperfections on the reference standard may be ignored. When reject filtering is used during UT testing, linearity must be demonstrated.

25.9.5 If, upon any standardization, the reference signal amplitude has decreased by at least 29 % (3.0 dB), the test apparatus shall be considered out of standardization. The test system settings may be changed, or the transducer(s), coil(s),or sensor(s) adjusted, and the unit restandardized, but all tubes tested since the last acceptable standardization must be retested.

25.10 Evaluation of Imperfections:

25.10.1 Tubing producing a test signal equal to or greater than the lowest signal produced by the reference standard shall be designated suspect, shall be clearly marked or identified,and shall be separated from the acceptable tubing.

25.10.2 Such suspect tubing shall be subject to one of the following three dispositions:

25.10.2.1 The tubes shall be rejected without further examination, at the discretion of the manufacturer.

25.10.2.2 If the test signal was produced by imperfections such as scratches, surface roughness, dings, straightener marks,loose ID bead and cutting chips, steel die stamps, stop marks,tube reducer ripple, or chattered flash trim, the tubing shall be accepted or rejected depending on visual observation of the severity of the imperfection, the type of signal it produces on the testing equipment used, or both.

25.10.2.3 If the test signal was produced by imperfections that cannot be identified, or was produced by cracks or crack-like imperfections, the tubing shall be rejected.

25.10.3 Any tubes with imperfections of the types in 25.10.2.2 and 25.10.2.3, exceeding 0.004 in. [0.1 mm] or 12.5 % of the specified minimum wall thickness (whichever is greater) in depth shall be rejected.

25.10.4 Rejected tubes may be reconditioned and retested providing the wall thickness is not decreased to less than that required by this or the product specification. If grinding is performed, the outside diameter in the area of grinding may be reduced by the amount so removed. To be accepted, reconditioned tubes must pass the nondestructive examination by which they were originally rejected.

26. Hydrostatic Test

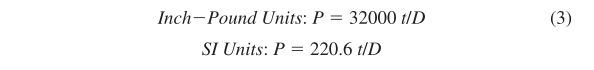

26.1 In lieu of nondestructive electric examination, and when specified by the purchaser, and, except as provided in 26.2 and 26.3, each tube shall be tested by the manufacturer to a minimum hydrostatic test pressure determined by the following equation:

where:

P = hydrostatic test pressure, psi or MPa,

t = specified wall thickness, in. or mm, and

D = specified outside diameter, in. or mm.

26.1.1 The hydrostatic test pressure determined by Eq 3 shall be rounded to the nearest 50 psi [0.5 MPa] for pressure below 1000 psi [7 MPa], and to the nearest 100 psi [1 MPa] for pressures 1000 psi [7 MPa] and above. The hydrostatic test may be performed prior to cutting to final length, or prior to upsetting, swaging, expanding, bending or other forming operations, or both.

26.2 Regardless of the determination made by Eq 3, the minimum hydrostatic test pressure required to satisfy these requirements need not exceed 1000 psi [7 MPa]. This does not prohibit testing at higher pressures at manufacturer’s option or as provided in 26.3.

26.3 With concurrence of the manufacturer, a minimum hydrostatic test pressure in excess of the requirements of 26.2 or 26.1, or both, may be stated on the order. The tube wall stress shall be determined by the following equation:

S = PD/2t (4)

where:

S = tube wall stress, psi or MPa, and all other symbols as defined in 24.1.

26.4 The test pressure shall be held for a minimum of 5 s.

26.5 If any tube shows leaks during the hydrostatic test, it shall be rejected.

26.6 The hydrostatic test may not be capable of testing the end portion of the pipe. The lengths of pipe that cannot be tested shall be determined by the manufacturer and, when specified in the purchase order, reported to the purchaser.

27. Pneumatic Test

27.1 Air Underwater Test—When this test is required, each tube, with internal surface clean and dry, shall be internally pressurized to 150 psi [1000 kPa] minimum with clean and dry compressed air while being submerged in clear water. The tube shall be well lighted, preferably by underwater illumination.Any evidence of air leakage of the pneumatic couplings shall be corrected prior to testing.Inspection shall be made of the entire external surface of the tube after holding the pressure for not less than 5 s after the surface of the water has become calm.If any tube shows leakage during the air underwater test, it shall be rejected.Any leaking areas may be cut out and the tube retested.

27.2 Air Pressure Test—When agreed to by the purchaser and supplier, a pneumatic pressure test in accordance with Test Method A1047/A1047M may be used in lieu of the air underwater test.

Acceptance criteria shall be as follows:

| ≤1.5 [≤40] | 0.003 [0.076] |

| >1.5 ≤2.0 [>40 ≤50] | 0.004 [0.162] |

| >2.0 ≤2.5 [>50 ≤65] | 0.005 [0.127] |

| >2.5 ≤3.0 [>65 ≤75] | 0.006 [0.152] |

| >3.0 [>7.5] | By agreement |

28. Certification and Test Reports

28.1 The producer or supplier shall furnish a certificate of compliance stating that the material was manufactured,sampled, tested, and inspected in accordance with the specification, including year date, the supplementary requirements,and any other requirements designated in the purchase order or contract, and the results met the requirements of that specification, the supplementary requirements and the other requirements. A signature or notarization is not required on the certificate of compliance, but the document shall be dated and shall clearly identify the organization submitting the report. Notwithstanding the absence of a signature or notarization, the certifying organization is responsible for the contents of the document.

28.2 In addition to the certificate of compliance, the manufacturer shall furnish test reports that include the following information and test results, where applicable:

28.2.1 Heat number,

28.2.2 Heat analysis,

28.2.3 Product analysis, when specified,

28.2.4 Tensile properties,

28.2.5 Width of the gage length, when longitudinal strip tension test specimens are used,

28.2.6 Flattening test acceptable,

28.2.7 Reverse flattening test acceptable,

28.2.8 Flaring test acceptable,

28.2.9 Flange test acceptable,

28.2.10 Hardness test values,

28.2.11 Hydrostatic test pressure,

28.2.12 Nondestructive electric test method,

28.2.13 Impact test results, and

28.2.14 Any other test results or information required to be reported by the product specification or the purchase order or contract.

28.3 The manufacturer shall report, along with the test report or in a separate document, any other information that is required to be reported by the product specification or the purchase order or contract.

28.4 The certificate of compliance shall include a statement of explanation for the letter added to the specification number marked on the tubes (see 30.3) when all of the requirements of the specification have not been completed. The purchaser must certify that all requirements of the specification have been completed before the removal of the letter (that is, X, Y, or Z).

28.5 A test report, certificate of compliance, or similar document printed from or used in electronic form from an electronic data interchange (EDI) transmission shall be regarded as having the same validity as a counterpart printed in the certifier’s facility. The content of the EDI transmitted document shall meet the requirements of the invoked ASTM standard(s) and conform to any existing EDI agreement between the purchaser and supplier. Notwithstanding the absence of a signature, the organization submitting the EDI transmission is responsible for the content of the report.

29. Inspection

29.1 The manufacturer shall afford the purchaser’s inspector all reasonable facilities necessary to be satisfied that the product is being produced and furnished in accordance with the ordered product specification. Mill inspection by the purchaser shall not interfere with the manufacturer’s operations.

30. Rejection

30.1 Each length of tubing received from the manufacturer may be inspected by the purchaser and, if it does not meet the requirements of the ordered product specification based on the inspection and test method as outlined in the ordered product specification, the length shall be rejected and the manufacturer shall be notified. Disposition of rejected tubing shall be a matter of agreement between the manufacturer and the purchaser.

30.2 Material that fails in any of the forming operations or in the process of installation and is found to be defective shall be set aside and the manufacturer shall be notified for mutual evaluation of the material’s suitability. Disposition of such material shall be a matter for agreement.

31. Product Marking

31.1 Each length of tube shall be legibly stenciled with the manufacturer’s name or brand, the specification number, and grade. The marking need not include the year of issue of the specification. For tubes less than 1 1 ⁄ 4 in. [31.8 mm] in diameter and tubes under 3 ft [1 m] in length, the required information may be marked on a tag securely attached to the bundle or box in which the tubes are shipped.

31.2 For austenitic steel pipe, the marking paint or ink shall not contain detrimental amounts of harmful metals, or metal salts, such as zinc, lead, or copper, which cause corrosive attack on heating.

31.3 When it is specified that certain requirements of a specification adopted by the ASME Boiler and Pressure Vessel Committee are to be completed by the purchaser upon receipt of the material, the manufacturer shall indicate that all requirements of the specification have not been completed by a letter such as X, Y, or Z, immediately following the specification number. This letter may be removed after completion of all requirements in accordance with the specification. An explanation of specification requirements to be completed is pro-

vided in 28.4.

31.4 Bar Coding—In addition to the requirements in 31.1-31.3, the manufacturer shall have the option of using bar coding as a supplementary identification method. Bar coding should be consistent with the (AIAG) standard prepared by the Primary Metals Subcommittee of the AIAG Bar Code Project Team.

32. Packaging, Marking, and Loading

32.1 When specified on the purchase order, packaging,marking, and loading for shipment shall be in accordance with the procedures of Practices A700.

33. Government Procurement

33.1 Scale Free Tube:

33.1.1 When specified in the contract or order, the following requirements shall be considered in the inquiry contract or order, for agencies of the U.S. Government where scale-free tube is required. These requirements shall take precedence if there is a conflict between these requirements and the product specification.

33.1.2 Tube shall be ordered to outside diameter (OD) and wall thickness.

33.1.3 Responsibility for Inspection—Unless otherwise specified in the contract or purchase order, the manufacturer is responsible for the performance of all inspection and test requirements specified. The absence of any inspection requirements in the specification shall not relieve the contractor of the responsibility for ensuring that all products or supplies submitted to the government for acceptance comply with all requirements of the contract. Sampling inspection, as part of the manufacturing operations, is an acceptable practice to ascertain conformance to requirements, however, this does not authorize submission of known defective material, either indicated or actual, nor does it commit the government to accept the material. Except as otherwise specified in the contract or purchase order, the manufacturer may use his own or any other suitable facilities for the performance of the inspection and test requirements unless disapproved by the purchaser at the time the order is placed. The purchaser shall have the right to perform any of the inspections and tests set forth when such inspection and tests are deemed necessary to ensure that the material conforms to the prescribed requirements.

33.1.4 Sampling for Flattening and Flaring Test and for Visual and Dimensional Examination—Minimum sampling for flattening and flaring tests and visual and dimensional examination shall be as follows:

| Lot Size (pieces per lot) | Sample Size |

| 2 to 8 | Entire lot |

| 9 to 90 | 8 |

| 91 to 150 | 12 |

| 151 to 280 | 19 |

| 281 to 500 | 21 |

| 501 to 1200 | 27 |

| 1201 to 3200 | 35 |

| 3201 to 10 000 | 38 |

| 10 001 to 35 000 | 46 |

In all cases, the acceptance number is zero and the rejection number is one. Rejected lots may be screened and resubmitted for visual and dimensional examination. All defective items shall be replaced with acceptable items prior to lot acceptance.

33.1.5 Sampling for Chemical Analysis—One sample for chemical analysis shall be selected from each of two tubes chosen from each lot. A lot shall be all material poured from one heat.

33.1.6 Sampling for Tension and Bend Test—One sample shall be taken from each lot.Alot shall consist of all tube of the same outside diameter and wall thickness manufactured during an 8-h shift from the same heat of steel, and heat treated under the same conditions of temperature and time in a single charge in a batch type furnace, or heat treated under the same condition in a continuous furnace, and presented for inspection at the same time.

33.1.7 Hydrostatic and Ultrasonic Tests—Each tube shall be tested by the ultrasonic (when specified) and hydrostatic tests.

33.1.8 Tube shall be free from heavy oxide or scale. The internal surface of hot finished ferritic steel tube shall be pickled or blast cleaned to a free of scale condition equivalent to the CSa2 visual standard listed in SSPC-SP6. Cleaning shall be performed in accordance with a written procedure that has been shown to be effective. This procedure shall be available for audit.

33.1.9 In addition to the marking in Specification A530/A530M, each length of tube 1 ⁄ 4 in. outside diameter and larger shall be marked with the following listed information. Marking shall be in accordance with FED-STD-183 and MIL-STD-792:(a) Outside diameter, wall thickness, and length (b) Heat or lot identification number.

33.1.10 Tube shall be straight to within the tolerances specified in Table 7.

TABLE 7 Straightness Tolerances

| Specified OD (in.) | Specified wall thickness (in.) | Maximum curvature in any 3 ft (in.) |

Maximum curvature in total length (in.) |

| Up to 5.0, incl | Over 3 % OD to 0.5, incl | 0.030 | 0.010 * length, ft |

| Over 5.0 to 8.0, incl | Over 4 % OD to 0.75, incl | 0.045 | 0.015 * length, ft |

| Over 8.0 to 12.75, incl | Over 4 % OD to 1.0, incl | 0.060 | 0.020 * length, ft |

33.1.11 When specified, each tube shall be ultrasonically examined in accordance with MIL-STD-271, except that the notch depth in the calibration standard shall be 5 % of the wall thickness or 0.005 in., whichever is greater. Any tube that produces an indication equal to or greater than 100 % of the indication from the calibration standard shall be rejected.

33.1.12 The tube shall be free from repair welds, welded joints, laps, laminations, seams, visible cracks, tears, grooves,slivers, pits, and other imperfections detrimental to the tube as determined by visual and ultrasonic examination, or alternate tests, as specified.

33.1.13 Tube shall be uniform in quality and condition and have a finish conforming to the best practice for standard quality tubing. Surface imperfections such as handling marks,straightening marks, light mandrel and die marks, shallow pits,and scale pattern will not be considered injurious if the imperfections are removable within the tolerances specified for wall thickness or 0.005 in. [0.1 mm], whichever is greater. The bottom of imperfections shall be visible and the profile shall be rounded and faired-in.

33.1.14 No weld repair by the manufacturer is permitted.

33.1.15 Preservation shall be level A or commercial, and packing shall be level A, B, or commercial, as specified. Level A preservation and level A or B packing shall be in accordance with MIL-STD-163 and commercial preservation and packing shall be in accordance with Practices A700 or Practice D3951.

34. Keywords

34.1 alloy steel tube; austenitic stainless steel; duplex stainless steel; ferritic stainless steel; ferritic/austenitic stainless steel; heavily cold-worked steel tube; seamless steel tube;stainless steel tube; steel tube; welded steel tube

![field:title/]](/uploads/251210/1-251210164114F6.png)

![field:title/]](/uploads/241211/1-241211152454213.png)

![field:title/]](/uploads/220425/1-22042511053I30.jpg)

![field:title/]](/uploads/220414/1-220414214051492.jpg)

![field:title/]](/uploads/211104/1-211104121004V0.jpg)

![field:title/]](/uploads/211102/1-21110215254UP.jpg)

![field:title/]](/uploads/210923/1-2109231045325B.png)

![field:title/]](/uploads/200915/1-2009151K634949.jpg)