EN 10216-1 Seamless Steel Tubes For Pressure Purposes

EN 10216-1

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 1: Non-alloy steel tubes with specified room temperature properties

1 Scope

This European Standard specifies the technical delivery conditions for two qualities TR1 and TR2 of seamless tubes of circular cross section with specified room temperature properties made of non-alloy quality steel.

NOTE:Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied,needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references,the latest edition of the referenced document (including any amendments) applies.

EN 10020, Definition and classification of grades of steel

EN 10021, General technical delivery conditions for steel products

EN 10027-1, Designation systems for steels Part 1: Steel names

EN 10027-2, Designation systems for steels Part 2: Numerical system

EN 10052, Vocabulary of heat treatment terms for ferrous products

EN 10168, Steel products Inspection documents List of information and description

EN 10204, Metallic products Types of inspection documents

EN 10220, Seamless and welded steel tubes Dimensions and masses per unit length

CEN/TR 10261, Iron and steel European standards for the determination of chemical composition

EN 10266, Steel tubes, fittings and structural hollow sections Symbols and definitions of terms for use in product standards

EN ISO 148-1, Metallic materials Charpy pendulum impact test Part 1: Test method (ISO 148-1)

EN ISO 377, Steel and steel products Location and preparation of samples and test pieces for mechanical testing (ISO 377)

EN ISO 2566-1, Steel Conversion of elongation values Part 1: Carbon and low alloy steels(ISO 2566-1)

EN ISO 6892-1, Metallic materials Tensile testing Part 1: Method of test at room temperature(ISO 6892-1)

EN ISO 10893-1, Non-destructive testing of steel tubes Part 1:Automated electromagnetic testing of seamless and welded (except submerged arc-welded) steel tubes for the verification of hydraulic leaktightness (ISO 10893-1)

EN ISO 10893-2, Non-destructive testing of steel tubes Part 2: Automated eddy current testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of imperfections (ISO 10893-2)

EN ISO 10893-3,Non-destructive testing of steel tubes Part 3: Automated full peripheral flux leakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detection of longitudinal and/or transverse imperfections (ISO 10893-3)

EN ISO 10893-10, Non-destructive testing of steel tubes Part 10: Automated full peripheral ultrasonic testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of longitudinal and/or transverse imperfections (ISO 10893-10)

EN ISO 14284,Steel and iron Sampling and preparation of samples for the determination of chemical composition (ISO 14284)

ISO 11484, Steel products Employer's qualification system for nondestructive testing (NDT) personnel

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 10020, EN 10021, EN 10052,EN 10266 and the following apply.

3.1

employer

organization for which a person works on a regular basis

Note 1 to entry: The employer may be either the tube manufacturer or a third party organization providing non-destructive testing (NDT) services.

4 Symbols

For the purpose of this Part of EN 10216, the symbols given in EN 10266 apply.

5 Classification and designation

5.1 Classification

According to the classification system in EN 10020, the steels are classified as non-alloy quality steels.

5.2 Designation

5.2.1 For the tubes covered by this Part of EN 10216 the steel designation consists of:

the number of this Part of EN 10216;

plus either:

the steel name in accordance with EN 10027-1;

or:

the steel number allocated in accordance with EN 10027-2.

5.2.2 The steel name is designated by:

the capital letter P for pressure purposes;

the indication of the specified minimum yield strength for thickness ≤ 16 mm, expressed in MPa(see Table 5 and Table 6);

plus either:

the alphanumeric TR1 for qualities without specified aluminium content, impact properties and specific inspection and testing requirements (see 9.1);

or:

the alphanumeric TR2 for qualities with specified aluminium content, impact properties and specific inspection and testing requirements.

6 Information to be supplied by the purchaser

6.1 Mandatory information

The following information shall be supplied by the purchaser at the time of enquiry and order:

the quantity (mass or total length or number);

the term “tube”;

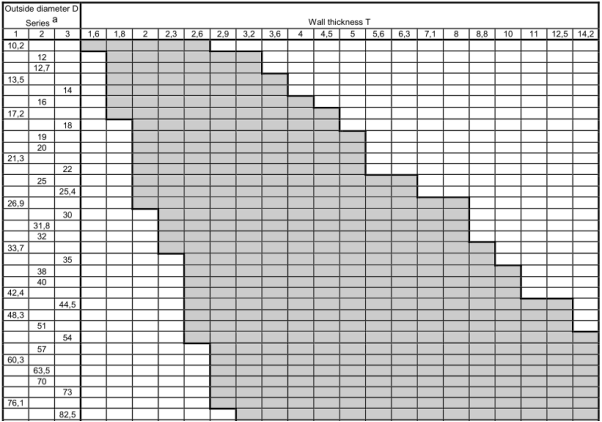

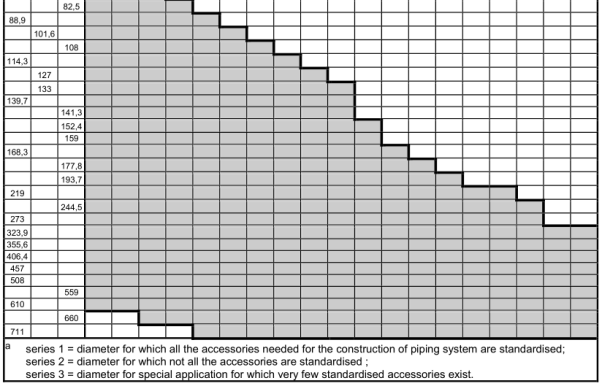

the dimensions (outside diameter D and wall thickness T) (see Table 7);

the designation of the steel grade in accordance with this Part of EN 10216 (see 5.2).

6.2 Options

A number of options are specified in this Part of EN 10216 and these are listed below. In the event that the purchaser does not indicate a wish to implement any of these options at the time of enquiry and order, the tubes shall be supplied in accordance with the basic specification (see 6.1).

1) Delivery condition normalized or normalizing-formed for TR1 (see 7.2.2);

2) restriction on copper and tin contents (see Table 2 and Table 3);

3) product analysis (see 8.2.2);

4) verification of longitudinal impact testing at −10 °C for quality TR2 (see Table 5 and Table 6);

5) selection of method for verification of leak-tightness (see 8.4.2.1);

6) Non-Destructive Testing for quality TR2 (see 8.4.2.2); the test method shall be specified by the purchaser;

7) special end preparation (see 8.6);

8) exact lengths (see 8.7.3);

9) inspection document 3.2 other than the standard document (see 9.2.1);

10) test unit restriction for tubes with D ≤ 76,1 mm of quality TR2 (see 10.1.1);

11) wall thickness measurement away from the ends (see 11.5);

12) additional marking (see 12.2);

13) protection (see 13).

6.3 Example of an order

100 t of seamless tube with an outside diameter of 168.3 mm, a wall thickness of 4,5 mm, in accordance with EN 10216-1, made of steel grade P235TR2 with a 3.2 inspection certificate in accordance with EN 10204.

EXAMPLE 100 t - Tube – 168,3 × 4,5 - EN 10216-1 - P235TR2 - 3.2.

7 Manufacturing process

7.1 Steelmaking process

The steelmaking process is at the discretion of the manufacturer with the exception that the open hearth (Siemens-Martin) process shall not be employed unless in combination with a secondary steelmaking or ladle refining process.

Steels shall be fully killed.

NOTE This excludes the use of rimming, balanced or semi-killed steel.

7.2 Tube manufacture and delivery conditions

7.2.1 All NDT activities shall be carried out by qualified and competent level 1,2 and/or 3 personnel authorized to operate by the employer.

The qualification shall be in accordance with ISO 11484 or, at least, an equivalent to it.

It is recommended that the level 3 personnel be certified in accordance with EN ISO 9712 or, at least, an equivalent to it.

The operating authorization issued by the employer shall be in accordance with a written procedure.

NDT operations shall be authorized by level 3 NDT individual approved by the employer.

NOTE The definition of level 1, 2 and 3 can be found in appropriate standards, e.g. EN ISO 9712 and ISO 11484.

7.2.2 The tubes shall be manufactured by a seamless process. The forming operations and delivery conditions are shown in Table 1.

Table 1 — Forming operations and delivery conditions

| Forming operation | Quality | Delivery condition |

| Hot formed | TR1 | As formed or normalized or normalizing-formed a |

| TR2 | Normalized or normalizing-formed | |

| Hot formed + cold finished | TR1 and TR2 | Normalized |

| a At the discretion of the manufacturer unless option 1 is specified. |

8 Requirements

8.1 General

When supplied in a delivery condition indicated in 7.2 and inspected in accordance with Clauses 9, 10 and 11,the tubes shall conform to the requirements of this Part of EN 10216.

In addition, the general technical delivery requirements specified in EN 10021 shall apply.

8.2 Chemical composition

8.2.1 Cast analysis

The cast analysis reported by the steel producer shall apply and conform to the requirements of Table 2 for quality TR2 and in Table 3 for quality TR1.

When welding tubes are produced in accordance with this Part of EN 10216, account should be taken of the fact that the behaviour of the steel during and after welding is dependent not only on the steel, but also on the applied heat treatment and the conditions of preparing for and carrying out the welding.

Table 2 — Chemical composition (cast analysis) a in % by mass for quality TR2

| Steel grade |

C max. |

Si max. |

Mn max. |

P max. |

S max. |

Cr b max. |

Mo b max |

Ni b max. |

Al tot min. |

Cu b c max |

Nb b max. |

Ti b max. |

V b max. |

Cr+Cu+Mo+Ni b max. |

|

|

Steel name |

Steel number |

||||||||||||||

| P195TR2 | 1.0108 | 0,13 | 0,35 | 0,70 | 0,025 | 0,015 | 0,30 | 0,08 | 0,30 |

0,02 d |

0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

| P235TR2 | 1.0255 | 0,16 | 0,35 | 1,20 | 0,025 | 0,015 | 0,30 | 0,08 | 0,30 |

0,02 d |

0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

| P265TR2 | 1.0259 | 0,20 | 0,40 | 1,40 | 0,025 | 0,015 | 0,30 | 0,08 | 0,30 |

0,02 d |

0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

|

a Elements not included in this table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process. b The content of these elements need not be reported unless intentionally added to the cast. c Option 2:In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply. d This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements which shall be reported. |

|||||||||||||||

Table 3 —Chemical composition (cast analysis) a in % by mass for quality TR1

| Steel grade |

C max. |

Si max. |

Mn max. |

P max. |

S max. |

Cr b max. |

Mo b max |

Ni b max. |

Al tot min. |

Cu b c max |

Nb b max. |

Ti b max. |

V b max. |

Cr+Cu+Mo+Ni b max. |

|

|

Steel name |

Steel number |

||||||||||||||

| P195TR1 d | 1.0107 | 0,13 | 0,35 | 0,70 | 0,025 | 0,020 | 0,30 | 0,08 | 0,30 | - | 0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

| P235TR1 d | 1.0254 | 0,16 | 0,35 | 1,20 | 0,025 | 0,020 | 0,30 | 0,08 | 0,30 | - | 0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

| P265TR1 d | 1.0258 | 0,20 | 0,40 | 1,40 | 0,025 | 0,020 | 0,30 | 0,08 | 0,30 | - | 0,30 | 0,010 | 0,04 | 0,02 | 0,70 |

|

a Elements not included in this table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process. b The content of these elements need not be reported unless intentionally added to the cast. c Option 2:In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply. d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC. |

|||||||||||||||

8.2.2 Product analysis

Option 3: A product analysis for tubes of quality TR2 shall be supplied. For tubes with outside diameter less than or equal to 76, 1 mm this option applies only in combination with Option 11.

Table 4 specifies the permissible deviations of the product analysis from the specified limits on cast analysis given in Table 2 and Table 3.

Table 4 —Permissible deviations of the product analysis from specified limits on cast analysis given in Tables 2 and 3

| Element |

Limiting value for the cast analysis in accordance with Table 2 % by mass |

Permissible deviation of the product analysis % by mass |

| C | ≤ 0,20 | + 0,02 |

| Si | ≤ 0,40 | + 0,05 |

| Mn | ≤ 1,40 | + 0,10 |

| P | ≤ 0,025 | + 0,005 |

| S |

≤ 0,020 for TR1 ≤ 0,015 for TR2 |

+ 0,005 + 0,003 |

| Al | ≥ 0,020 | − 0,005 |

| Cr | ≤ 0,30 | + 0,05 |

| Cu | ≤ 0,30 | + 0,05 |

| Mo | ≤ 0,08 | + 0,02 |

| Nb | ≤ 0,010 | + 0,005 |

| Ni | ≤ 0,30 | + 0,005 |

| Ti | ≤ 0,04 | + 0,01 |

| V | ≤ 0,02 | + 0,01 |

8.3 Mechanical properties

8.3.1 Mechanical properties for quality TR2

The mechanical properties of the tubes shall conform to the requirements of Table 5 for grade TR2 irrespective of whether they are verified or not (see Table 11).

Table 5 — Mechanical properties for quality TR2 a

| Steel grade | Tensile properties |

Impact properties |

Impact properties | |||||||

| Steel name |

Steel number |

Upper yield strength R eH b min. for Wall Thickness T mm |

Tensile Strength R m |

Elongation A min. % b c |

Minimum average absorbed energy KV 2 J at a temperature of °C c |

|||||

| T ≤ 16 | 16 < T ≤ 40 |

40 < T ≤ 60 |

l | t | ||||||

| MPa * | MPa * | MPa * | MPa * | l | t | 0 | -10 | 0 | ||

| P195TR2 | 1.0108 | 195 | 185 | 175 | 320 to 440 | 27 | 25 | 40 | 28 d | 27 |

| P235TR2 | 1.0255 | 235 | 225 | 215 | 320 to 440 | 25 | 23 | 40 | 28 d | 27 |

| P265TR2 | 1.0259 | 265 | 255 | 245 | 410 to 570 | 21 | 19 | 40 | 28 d | 27 |

|

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement. b See 11.2. c l = longitudinal t = transverse d Option 4: In addition to the test in Table 11, longitudinal impact strength shall be verified at - 10 °C. *1 MPa = 1 N/mm 2 |

||||||||||

8.3.2 Mechanical properties for quality TR1

The mechanical properties of the tubes shall conform to the requirements of Table 6 for grade TR1 irrespective of whether they are verified or not (see Table 10).

Table 6 — Mechanical properties for quality TR1 a

| Steel grade | Tensile properties | Impact properties | ||||||||

|

Steel name |

Steel number |

Upper yield strength R eH b min. for Wall Thickness T mm |

Tensile Strength R m |

Elongation A min. % b c |

Minimum average absorbed energy KV 2 J at a temperature of °C c |

|||||

| T ≤ 16 | 16 < T ≤ 40 |

40 < T ≤ 60 |

l | t | ||||||

| MPa * | MPa * | MPa * | MPa * | l | t | 0 | -10 | 0 | ||

| P195TR1 d | 1.0107 | 195 | 185 | 175 | 320 to 440 | 27 | 25 | - | - | - |

| P235TR1 d | 1.0254 | 235 | 225 | 215 | 360 to 550 | 25 | 23 | - | - | - |

| P265TR1 d | 1.0258 | 265 | 255 | 245 | 410 to 570 | 21 | 19 | - | - | - |

|

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement. b See 11.2. c l = longitudinal t = transverse d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC. * 1 MPa = 1 N/mm |

||||||||||

8.4 Appearance and internal soundness

8.4.1 Appearance

8.4.1.1 The tubes shall be free from external and internal surface defects that can be detected by visual examination.

8.4.1.2 The internal and external surface finish of the tubes shall be typical of the manufacturing process and,where applicable, the heat treatment employed. Normally the finish and surface condition shall be such that any surface imperfections requiring dressing can be identified.

8.4.1.3 It shall be permissible to dress, only by grinding or machining, surface imperfections provided that,after doing so, the wall thickness in the dressed area is not less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the tube.

8.4.1.4 Surface imperfections which encroach on the specified minimum wall thickness shall be considered defects and tubes containing these shall be deemed not to conform to this Part of this EN 10216.

8.4.2 Internal soundness

8.4.2.1 Leak-tightness

The tubes shall pass a hydrostatic test (see 11.4.1) or electromagnetic test (see 11.4.2) for leak-tightness.Unless the Option 5 is specified the choice of the test method is at the discretion of the manufacturer.

Option 5: The test method for verification of leak-tightness in accordance with 11.4.1 or 11.4.2 is specified by the purchaser.

8.4.2.2 Non-Destructive Testing

Option 6: The tubes of quality TR2 shall pass a non-destructive test for the detection of longitudinal imperfections in accordance with 11.7. The test method shall be specified by the purchaser

8.5 Straightness

The deviation from straightness, of any tube length L shall not exceed 0,001 5 L. Deviations from straightness over any one metre length shall not exceed 3 mm.

8.6 Preparation of ends

Tubes with wall thickness ≥ 3,2 mm shall be delivered with square cut ends. The ends shall be free from excessive burrs.

Option 7: The tubes with wall thickness ≥ 3.2 mm shall be delivered with bevelled ends (see Figure 1). The bevel shall have an angle α of 30°( +°5,-0°)with a root face C of 1,6 mm ± 0,8 mm, except that for wall thickness T greater than 20 mm, an agreed alternative bevel may be specified.

Key

D outside diameter

α bevel angle

C root face of bevelled end

8.7 Dimensions, masses and tolerances

8.7.1 Diameter and wall thickness

Tubes shall be delivered by outside diameter D and wall thickness T.

Preferred outside diameters D and wall thicknesses T have been selected from EN 10220 and are given in Table 7.

Dimensions which are different from those in Table 7 may be agreed.

8.7.2 Mass

For the mass per unit length the provisions of EN 10220 apply.

8.7.3 Lengths

Unless Option 8 is specified the tubes are delivered in random lengths. The delivery range shall be agreed at the time of enquiry and order.

Option 8: The tubes shall be delivered in exact lengths and the length shall be specified at the time of enquiry and order. For the tolerances, see 8.7.4.2.l

8.7.4 Tolerances

8.7.4.1 Tolerances on diameter and thickness

The diameter and the wall thickness of the tubes shall be within the tolerance limits given in Table 8.

Out-of-roundness is included in the tolerances on outside diameter and eccentricity is included in the tolerances on wall thickness.

Table 8 — Tolerances on outside diameter and on wall thickness

|

Outside diameter D mm |

Tolerances on D | Tolerances on T for a T/D ratio | |||

| ≤ 0,025 |

> 0,025 ≤ 0,050 |

> 0,050 ≤ 0,10 |

> 0,10 | ||

| D ≤ 219,1 | ± 1% or ± 0,5 mm whichever is the greater |

± 12,5 % or ± 0,4 mm whichever is the greater |

|||

| D > 219,1 | ± 20 % | ± 15 % | ± 12,5 % | ± 10 % a | |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5 % of the wall thickness T | |||||

8.7.4.2 Tolerances on exact lengths

The tolerances for exact lengths shall be as given in Table 9.

| Length L | Tolerance on exact length |

| L ≤ 6 000 |

+ 10 0 |

| 6 000 < L ≤ 12 000 |

+15 0 |

| L > 12 000 |

+by agreement 0 |

9 Inspection

9.1 Types of inspection

Conformity to the requirements of the order, for tubes in accordance with this Part of EN 10216, shall be verified by:

non-specific or specific inspection for quality TR1;

specific inspection for quality TR2.

When an inspection certificate 3.1 is specified, the material manufacturer shall state in the confirmation of the order whether he is operating according to a “quality-assurance system”, certified by a competent Body established within the Community, and having undergone a specific assessment for materials.

NOTE See the EU Directive 97/23/EC, Annex I, section 4.3 third paragraph and for further information the Guidelines of the EU Commission and the Member States for its interpretation (see e.g. Guidelines 7/2 and 7/16).

9.2 Inspection documents

9.2.1 Types of inspection documents

The following inspection documents, in accordance with EN 10204, shall be issued;

- test report 2.2 for quality TR1;

- inspection certificate 3.1 for quality TR2.

Option 9: One of the following inspection documents, specified by the purchaser, shall be issued:

- for quality TR1 specific inspection with inspection certificate 3.2;

- for quality TR2, an inspection certificate 3.2.

If an inspection certificate 3.2 is specified, the purchaser shall notify the manufacturer of the name and address of the organization or person who is to carry out the inspection and produce the inspection document, and it shall be agreed which party shall issue the certificate.

Document 3.1 and 3.2 are to be validated by the manufacturer’s authorized representative.

9.2.2 Content of inspection documents

9.2.2.1 The content of the inspection document shall be in accordance with EN 10168 as shown in 9.2.2.2 and9.2.2.3.

In all types of inspection documents, a statement on the conformity of the products delivered with the requirements of this specification and the order shall be included.

9.2.2.2 For tubes supplied with non-specific inspection, the test report shall contain the following codes and information:

A commercial transactions and parties involved;

B description of products to which the inspection document applies;

C02 direction of test pieces;

C10–C13 tensile test;

C71–C92 chemical composition;

D01 marking and identification, surface appearance, shape and dimensional properties;

D02–D99 leak-tightness test;

Z validation.

9.2.2.3 For tubes supplied with specific inspection the inspection certificate shall contain the following codes and information:

A commercial transactions and parties involved;

B description of products to which the inspection document applies

C02–C03 direction of test pieces and testing temperature;

C10–C13 tensile test;

C40–C43 impact test, if applicable;

C71–C92 chemical composition on cast analysis (product analysis if applicable);

D01 marking and identification, surface appearance, shape and dimensional properties;

D02–D99 leak-tightness test; NDT if applicable;

Z validation.

In addition, for inspection document 3.1 the manufacturer shall state the references to the certificate (see 9.1) of the appropriate “quality-assurance system“, if applicable

9.3 Summary of inspection and verification testing

Table 10 — Summary of inspection and verification testing for quality TR1

| Type of inspection and test | Frequency of testing | Refer to | ||

|

Non-specific inspection |

Specific inspection |

|||

|

Mandatory tests |

Cast analysis |

One representative result per delivery item |

One per cast | 8.2.1 and 11.1 |

| Tensile test | One per test unit | 8.3.2 and 11.2 | ||

| Leak-tightness test | Each tube | 11.4 | ||

| Dimensional inspection | See 11.5 | |||

| Visual examination | See 11.6 | |||

|

Optional test |

Wall thickness measurement away from tube ends (Option 12) |

See 11.5 |

Table 11 — Summary of inspection and verification testing for quality TR2

| Type of inspection and test | Frequency of testing | Refer to | |

| Mandatory tests | Cast analysis | One per cast | 8.2.1 and 11.1 |

| Tensile test | One per test unit | 8.3.1 and 11.2 | |

| Impact test at 0 °C | 8.3.1 and 11.3 | ||

| Leak-tightness test | Each tube | 11.4 | |

| Dimensional inspection | See 11.5 | ||

| Visual examination | See 11.6 | ||

| Optional tests | Product analysis (Option 3) | One per cast | 8.2.2 and 11.1 |

| Longitudinal impact test at -10 °C (Option 4) | One per test unit | 8.3.1 and 11.3 | |

| Wall thickness measurement away from tube ends (Option 12) | See 11.5 | ||

| NDT for detection of longitudinal imperfections (Option 6) | Each tube | 11.7 | |

10 Sampling

10.1 Frequency of tests

10.1.1 Test unit

In case of specific inspection, a test unit shall comprise:

Quality TR1: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace.

Quality TR2: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same cast, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace. Tubes with specified outside diameter less than or equal to 76.1 mm need not be separated by cast unless Option 10 is specified.

The number of tubes, in manufacturing lengths, per test unit shall conform to Table 12.

The manufacturing length (e.g. the rolled length after the normalising forming process) may differ from the delivery length providing there is no additional HT after cutting the manufacturing lengths into individual lengths.

Option 10: Tubes with specified outside diameter less than or equal to 76,1 mm shall be separated by cast for quality TR2 .

Table 12 — Number of tubes per test unit

| Outside diameter D(mm) | Maximum number of tubes per test unit | |

| Quality TR1 | Quality TR2 | |

| D ≤ 114,3 | 400 | 200 |

| 114,3 < D ≤ 323,9 | 200 | 100 |

| D > 323,9 | 100 | 50 |

10.1.2 Number of sample tubes per test unit

One sample tube shall be taken from each test unit.

10.2 Preparation of samples and test pieces

10.2.1 Selection and preparation of samples for product analysis Samples for product analysis shall be taken from the test pieces or samples for mechanical testing or from the whole thickness of the tube at the same location as the mechanical test samples, in accordance with EN ISO 14284.

10.2.2 Location, orientation and preparation of samples and test pieces for mechanical tests

10.2.2.1 General

Samples and test pieces shall be taken at the tube ends and in accordance with the requirements of EN ISO 377.

10.2.2.2 Test pieces for tensile test

The test pieces for tensile test shall be prepared in accordance with EN ISO 6892-1.

At the manufacturer's discretion:

for tubes with an outside diameter D ≤ 219,1 mm the test piece shall be either a full tube section or a strip section and shall be taken in a direction longitudinal to the axis of the tube;

for tubes with an outside diameter D > 219,1 mm the test piece shall either a machined test piece with circular cross section from an unflattened sample or a strip section and be taken in a direction either longitudinal or transverse to the axis of the tube.

10.2.2.3 Test pieces for impact test

Three standard Charpy V-notch test pieces shall be prepared in accordance with EN ISO 148-1. If the wall thickness is such that standard test pieces cannot be produced without flattening of the section, then test pieces of width less than 10 mm, but not less than 5 mm shall be prepared; the largest obtainable width shall be used.

Where test pieces at least 5 mm width cannot be obtained, the tubes shall not be subjected to impact testing.

Unless otherwise specified (see Option 4), the test pieces shall be taken transverse to the tube axis unless D min , as calculated by the following equation, is greater than the specified outside diameter, in which case longitudinal test pieces shall be used:

D min = (T-5) + [ 756,25 / (T-5) ] (1)

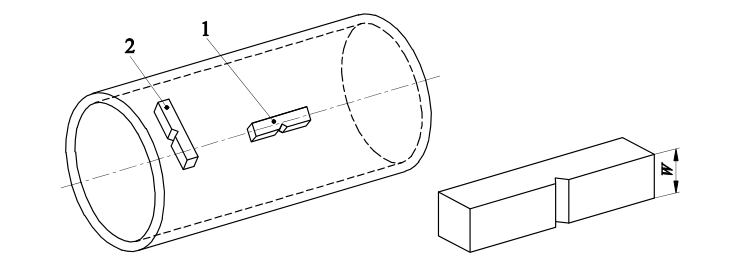

The test pieces shall be prepared such that the axis of the notch is perpendicular to the surface of the tube,see Figure 2.

1 longitudinal test piece

2 transverse test piece

w specimen width

11 Verification test methods

11.1 Chemical analysis

The elements to be determined and reported shall be those specified in Table 2. The choice of a suitable physical or chemical analytical method for the analysis shall be at the discretion of the manufacturer. In cases of dispute, the method used shall be agreed between manufacturer and purchaser taking into account CEN/TR 10261.

11.2 Tensile test

The test shall be carried out at room temperature in accordance with EN ISO 6892-1, and the following shall be determined:

the tensile strength (R m );

the upper yield strength (R eH ) or if a yield phenomenon is not present the 0,2 % proof strength (R p0,2 );

the percentage elongation after fracture with a reference to a gauge length ( L 0 ) of So ⋅ 65 , 5 ; if a nonproportional test piece is used, the percentage elongation value shall be converted to the value for a gauge length So Lo ⋅ = 65 , 5 using the conversion tables in EN ISO 2566-1.

11.3 Impact test

11.3.1 The test shall be carried out (but see 10.2.2.3) in accordance with EN ISO 148-1 at 0 °C and, if option 4 is specified, at -10 °C.

11.3.2 The mean value of the three test pieces shall meet the requirements given in Table 5 and Table 6. One individual value may be below the specified value, provided that it is not less than 70 % of that value.

11.3.3 If the width (W) of the test piece is less than 10 mm, the measured impact energy (KV p ) shall be converted to the calculated impact energy( KV c ) using the following equation:

KV c is the calculated impact energy, in joules;

KV p is the measured impact energy, in joules;

W is the width of the test piece, in millimetres.

The calculated impact energy KV c shall conform to the requirements given in 11.3.2.

11.3.4 If the requirements of 11.3.2 are not met, then an additional set of three test pieces may be taken at the discretion of the manufacturer from the same sample and tested. To consider the test unit as conforming, after testing the second set, the following conditions shall be satisfied simultaneously:

the average value of the six tests shall be equal to or greater than the specified minimum value;

not more than two of the six individual values may be lower than the specified minimum value;

not more than one of the six individual values may be lower than 70 % of the specified minimum average value.

11.3.5 The dimensions in millimetres of the test pieces, the measured impact energy values and the resulting average value shall be reported.

11.4 Leak tightness test

11.4.1 Hydrostatic test

The hydrostatic test shall be carried out at a test pressure of 70 bar 1) or at a test pressure P calculated using the following equation, whichever is lower:

where

P is the test pressure, in bar;

D is the specified outside diameter, in millimetres;

T is the specified wall thickness, in millimetres;

S is the stress, in MPa, corresponding to 70 % of the specified minimum yield strength (see Table 5 and Table 6) for the steel grade concerned.

The test pressure shall be held for not less than 5 s for tubes with an outside diameter D less than or equal to 457 mm and for not less than 10 s for tubes with an outside diameter D greater than 457 mm.

The tube shall withstand the test without showing leakage.

NOTE This hydrostatic leak-tightness test is not a strength test.

11.4.2 Electromagnetic test

The test shall be carried out in accordance with EN ISO 10893-1.

11.5 Dimensional inspection

Specified dimensions, including straightness, shall be verified.

The outside diameter shall be measured at tube ends. For tubes with outside diameter D ≥ 406,4 mm, the diameter may be measured using a circumference tape.

Unless Option 11 is specified the wall thickness shall be measured at both tube ends.

Option 11: The wall thickness shall be measured away from the tube ends in accordance with an agreed procedure.

11.6 Visual examination

Tubes shall be visually examined to ensure conformity to the requirements of 8.4.1.

11.7 Non-Destructive Testing

When Option 6 is specified, the tubes of quality TR2 shall be subjected to Non-Destructive testing for the detection of longitudinal imperfections in accordance with EN ISO 10893-2, EN ISO 10893-3 or EN ISO 10893-10 to acceptance level 3, sub-category C, where applicable.

Regions at the tube ends not automatically tested shall either be subjected to manual/semi-automatic ultrasonic testing in accordance with EN ISO 10893-10 or be cropped off.

11.8 Retest, sorting and reprocessing

For retest, sorting and reprocessing the requirements of EN 10021 shall apply.

12 Marking

12.1 Marking to be applied

The marking shall be indelibly marked on each tube at least at one end. For tubes with outside diameter D ≤ 51 mm the marking on tubes may be replaced by the marking on a label attached to the bundle or box.

The marking shall include the following information:

the manufacturer's name or trade mark;

the number of this European Standard and the steel name (see 5.2).

In addition in case of specific inspection:

the cast number or a code number;

the mark of the inspection representative;

an identification number (e.g. order or item number), which permit the correlation of the product or delivery unit to related documents.

Example of marking:

EXAMPLE X – EN 10216-1 - P265TR2 - Y - Z 1 - Z 2

where

X is the manufacturer's mark;

Y is the cast number or the code number;

Z 1 is the mark of the inspection representative;

Z 2 is the identification number.

12.2 Additional marking

Option 12: Additional marking, as agreed upon at the time of the enquiry and order, shall be applied.

13 Protection

The tubes shall be delivered without a temporary protective coating.

Option 13: A temporary protective coating or durable coating and/or lining shall be applied.

![field:title/]](/uploads/251210/1-251210164114F6.png)

![field:title/]](/uploads/241211/1-241211152454213.png)

![field:title/]](/uploads/220425/1-22042511053I30.jpg)

![field:title/]](/uploads/220414/1-220414214051492.jpg)

![field:title/]](/uploads/211104/1-211104121004V0.jpg)

![field:title/]](/uploads/211102/1-21110215254UP.jpg)

![field:title/]](/uploads/210923/1-2109231045325B.png)

![field:title/]](/uploads/200915/1-2009151K634949.jpg)