Hot rolled vs Cold rolled steel tubing

Hot rolled and cold rolled are two kinds of manufacturing processes for seamless steel tubes.

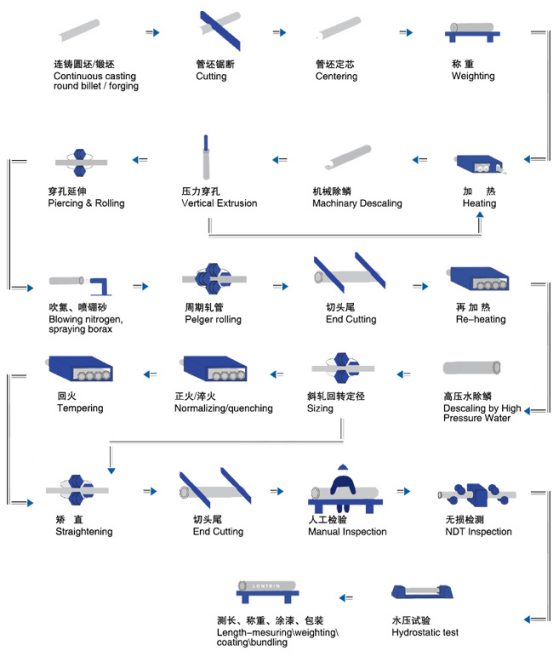

Hot rolled seamless steel tube manufacturing processTube blank preparation and inspection → Tube blank heating → Perforation → Rolling tube → Reheating of steel tube → Deciding (reduction) diameter → Heat treatment → Straightening of finished product pipe → Finishing → Inspection (non-destructive, physicochemical, and station inspection) → Storage

Cold rolled seamless steel tube manufacturing process

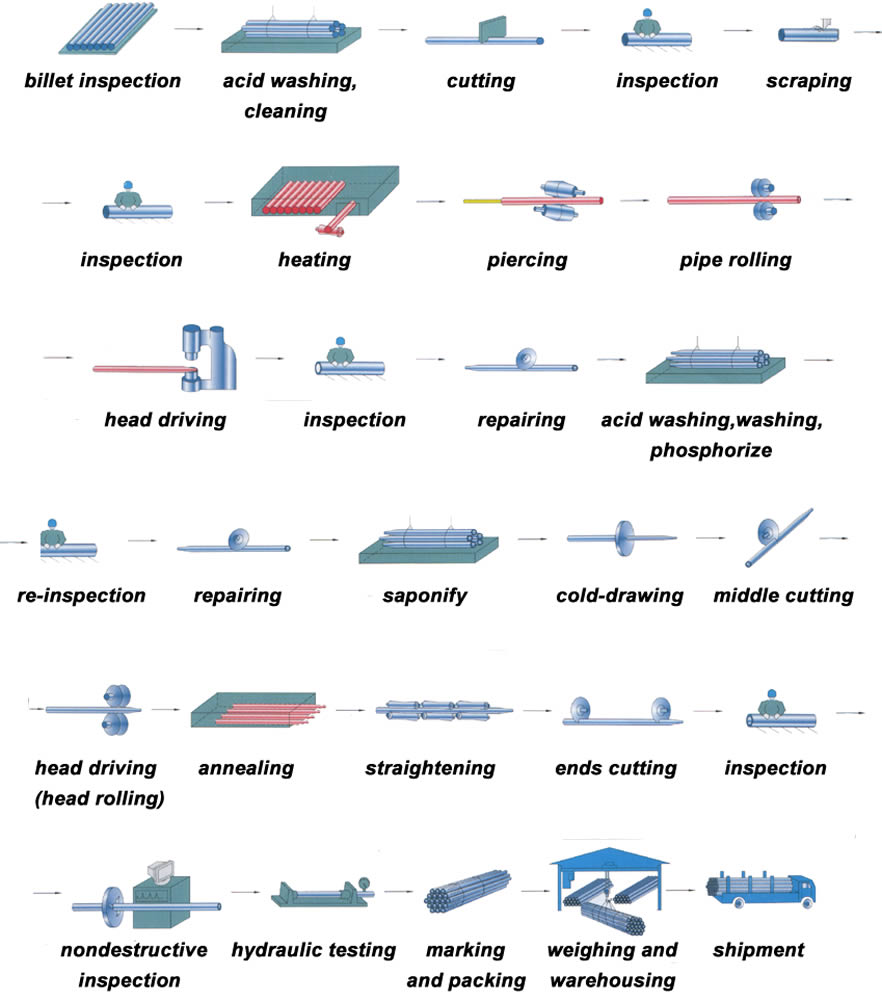

Round tube → heating → perforation → Heading → annealing → pickling → oiled (copper) → multi-pass cold drawn (cold rolled) → blank tube → heat treatment → straightening →hydrostatic testing (testing) → Mark → storage.

Hot rolled seamless steel pipe

Hot-rolled seamless pipe outer diameter is generally greater than 32mm, wall thickness 2.5-200mm, cold-rolled seamless steel pipe outer diameter can be to 6mm, wall thickness can be to 0.25mm, thin-walled pipe outer diameter to 5mm wall thickness is less than 0.25mm, cold Rolling has higher dimensional accuracy than hot rolling.

Advantages of hot-rolled seamless steel pipe

It can destroy the casting structure of the steel pipe, refine the grain of the steel pipe, and eliminate the defects of the microstructure, so that the seamless steel pipe is dense and the mechanical properties are improved.

The disadvantage of hot-rolled seamless steel pipe

1.After hot rolling, the non-metallic inclusions (mainly sulfides and oxides, and silicates) inside the seamless steel tube are pressed into thin sheets to cause delamination (interlayering). Stratification greatly degrades the ability of the steel to be pulled in the thickness direction.

2.Residual stress caused by uneven cooling. Residual stress is the stress of internal self-phase equilibrium under the condition of no external force. Hot rolled seamless steel tubes of various sections have such residual stress. The larger the section size of general steel, the greater the residual stress. The performance of seamless steel pipes under external forces still has some influence.

3.The hot rolling process does not have good control over the thickness and width of the seamless steel pipe. We are familiar with thermal expansion and contraction, because at the beginning of hot rolling even if the length, thickness are up to standard, and finally there will be a certain negative difference after cooling, the wider the width of the negative difference, the thicker the more obvious the performance. The seam width, thickness, length, angle, and edge of the seamless steel pipe can not be too exact.

Cold rolled seamless steel pipe

Advantages of Cold rolled seamless steel pipe

The advantages: the cold rolled seamless steel pipe has fast forming speed, high production and no damage to the coating. It can be made into a variety of cross section forms to meet the needs of the use conditions. Cold rolling can make the seamless steel pipe produce large plastic deformation and thus improve the yield point of seamless steel pipe.

The disadvantage of Cold rolled seamless steel pipe

1. the cold rolled seamless steel tube has no thermal plastic compression in the process of forming, but there is still residual stress in the section, which will inevitably affect the overall and local buckling of seamless steel tubes.

2. the cold-rolled seamless steel tube style is generally open section, so that the free torsion stiffness of the section is low. Torsion is prone to occur during bending, and flexural torsional buckling is prone to occur under compression.

3. the cold-rolled seamless steel tube has small wall thickness, and it is not thickened at the corner of plate joining.

Summary:

Cold rolled seamless steel tubes are often small diameter steel pipes, and hot-rolled seamless steel tubes are often large-diameter steel pipes.

The accuracy of cold-rolled seamless steel tubes is higher than that of hot-rolled seamless steel tubes, and the price is higher than that of hot rolled seamless steel tubes.

The hot rolled seamless tubes are divided into general steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy tubes, stainless steel pipes, oil cracking pipes, geological pipes and other steel pipes.

The cold rolled seamless steel tubes are divided into ordinary steel tubes, low medium pressure boiler tubes, high pressure boiler tubes, alloy tubes, stainless steel pipes, oil cracking tubes, and other steel pipes, including thin carbon thin steel tubes, alloy thin-walled steel tubes, stainless steel tubes and special-shaped steel tubes.

![field:title/]](/uploads/251210/1-251210164114F6.png)

![field:title/]](/uploads/241211/1-241211152454213.png)

![field:title/]](/uploads/220425/1-22042511053I30.jpg)

![field:title/]](/uploads/220414/1-220414214051492.jpg)

![field:title/]](/uploads/211104/1-211104121004V0.jpg)

![field:title/]](/uploads/211102/1-21110215254UP.jpg)

![field:title/]](/uploads/210923/1-2109231045325B.png)

![field:title/]](/uploads/200915/1-2009151K634949.jpg)